The French company Brûlé et Cie originally made front-drive tractors. After encountering many complaints, it looks that they took that front-drive unit, making it a single and universal unit. Now this could be mounted under every thinkable vehicle. This front-drive unit consisted of a rotatable frame with a three-cylinder Roser-Mazurier engine, an open transmission, but no differential. The whole could pivote, making this one of the first continental front-drive units. Unfortunately, I couldn’t find information on it’s possible succes and manufactured numbers.

With authorisation of Bibliothèque national francais, gallica.bnf.fr.

Text and photos compiled byr motorracingistory.com, translation by DeepL.com

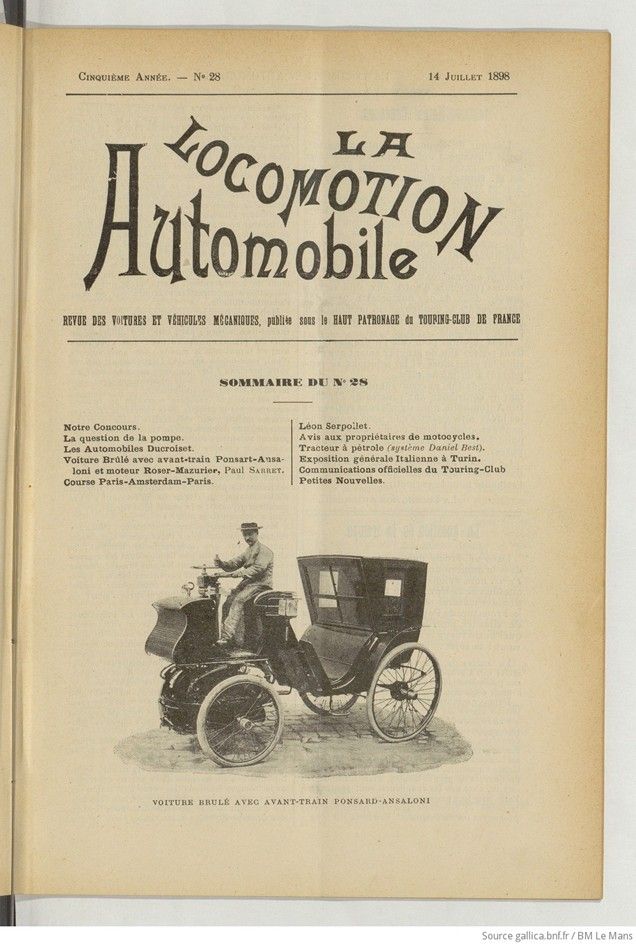

La Locomotion Automobile, Vol. 5, No. 28, July 14, 1898

The Brûlé car

with Ponsard-Ansaloni front-end and Roser-Mazurier engine

The mechanical engineering company Brûlé et Cie (formerly Hermann-Lachapelle) exhibited a car with a Ponsard-Ansaloni front end and engine at the Tuileries this year. The original idea for the system was derived from the first attempts at mechanical tractors for towing ordinary carriages, but the tractors were criticized for their unsightly appearance and considerable weight. Here, there is nothing of the sort. The cars are also completely interchangeable, but the entire mechanism is attached to the front axle, which is both the engine and the steering mechanism. It can be easily installed in place of the front axle of a standard car, which can thus be instantly converted into an automobile with the help of a few bolts. The car thus transformed retains its general appearance and all the comfort of the ordinary bodywork. In addition, as the engine is located at the front, the car is pulled rather than pushed, which makes steering safer. The mechanism’s components are easily accessible and can be inspected and lubricated instantly while on the road.

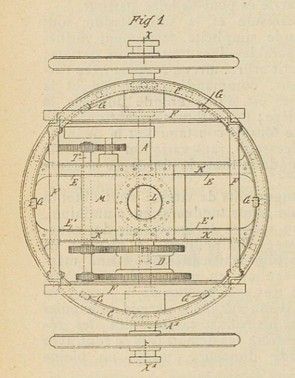

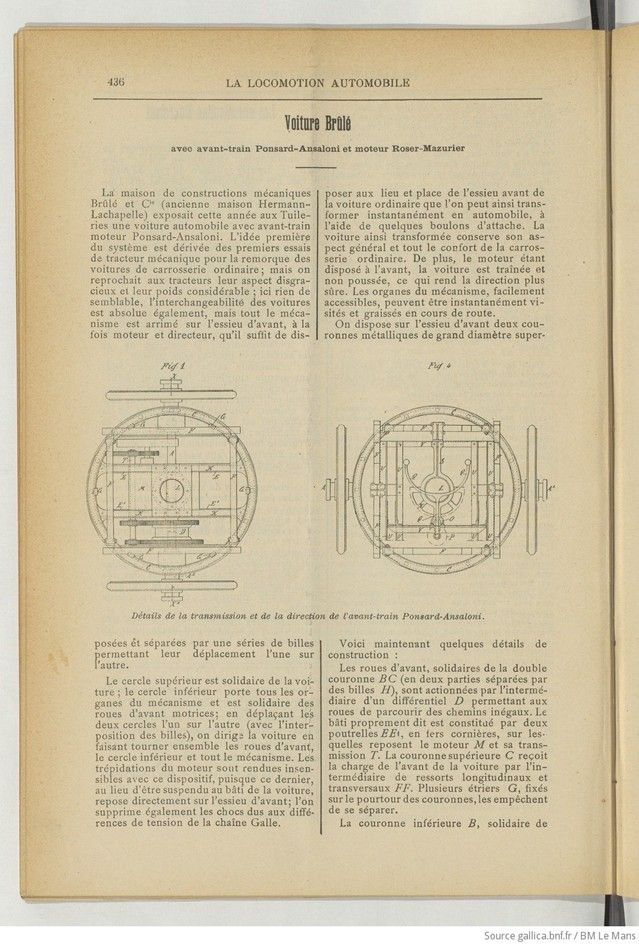

Two large-diameter metal rings are placed on the front axle, one on top of the other and separated by a series of balls that allow them to move on top of each other.

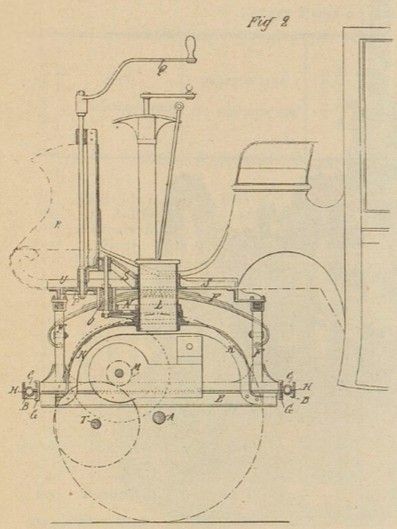

The upper ring is attached to the car; the lower ring carries all the parts of the mechanism and is attached to the front drive wheels; by moving the two rings over each other (with the interposition of the balls), the car is steered by turning the front wheels, the lower ring, and the entire mechanism together. Engine vibrations are rendered imperceptible with this device, since it rests directly on the front axle instead of being suspended from the car frame; Shocks caused by differences in tension in the Galle chain are also suppressed.

Here now some construction details:

The front wheels, which are connected to the double crown BC (in two parts separated by balls H), are driven by a differential D, allowing the wheels to travel on uneven roads. The frame itself consists of two EE1 angle iron beams, on which the M engine and its T transmission rest. The upper C crown bears the load of the front of the car via FF longitudinal and transverse springs. Several G brackets, fixed to the perimeter of the crowns, prevent them from separating.

The lower ring B, which is integral with the axle and the mechanism, is the only one that moves: it is attached by rigid hoops K to a vertical tube Z, placed in Taxe like a kingpin. A toothed sector N is bolted to this tube and receives the steering movement via the pinions O and P and transmits it to the mobile ring B.

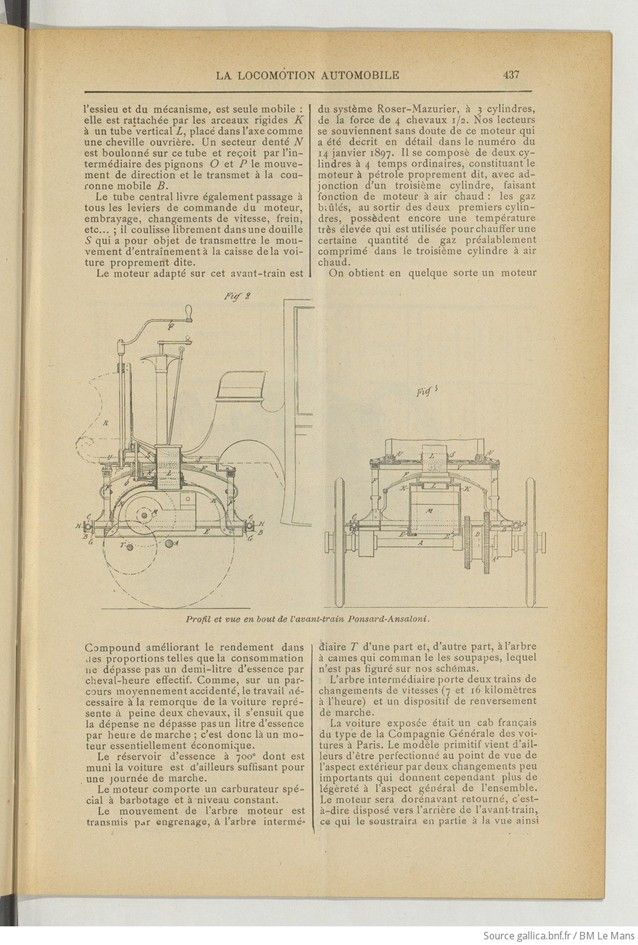

The central tube also provides access to all the engine control levers, clutch, gear changes, brakes, etc.; it slides freely in a sleeve S, the purpose of which is to transmit the drive movement to the car body itself.

The engine fitted to this front end is a Roser-Mazurier system, with three cylinders and a power output of 4½ horsepower. Our readers will no doubt remember this engine, which was described in detail in the January 14, 1897 issue. It consists of two ordinary 4-stroke cylinders, constituting the actual petrol engine, with the addition of a third cylinder, acting as a hot air engine: the exhaust gases from the first two cylinders are still at a very high temperature, which is used to heat a certain amount of gas previously compressed in the third hot air cylinder.

The result is a kind of compound engine that improves efficiency to such an extent that consumption does not exceed half a liter of gasoline per effective horsepower-hour. Since, on a moderately hilly route, the work required to tow the car represents barely two horsepower, it follows that consumption does not exceed one liter of gasoline per hour of operation; this is therefore an essentially economical engine.

The 700° gasoline tank fitted to the car is sufficient for a day’s driving.

The engine has a special constant-level float carburetor.

The movement of the drive shaft is transmitted by gears to the intermediate shaft T on the one hand and, on the other hand, to the camshaft that controls the valves, which is not shown in our diagrams. The intermediate shaft carries two gear trains (7 and 16 kilometers per hour) and a reverse gear device..

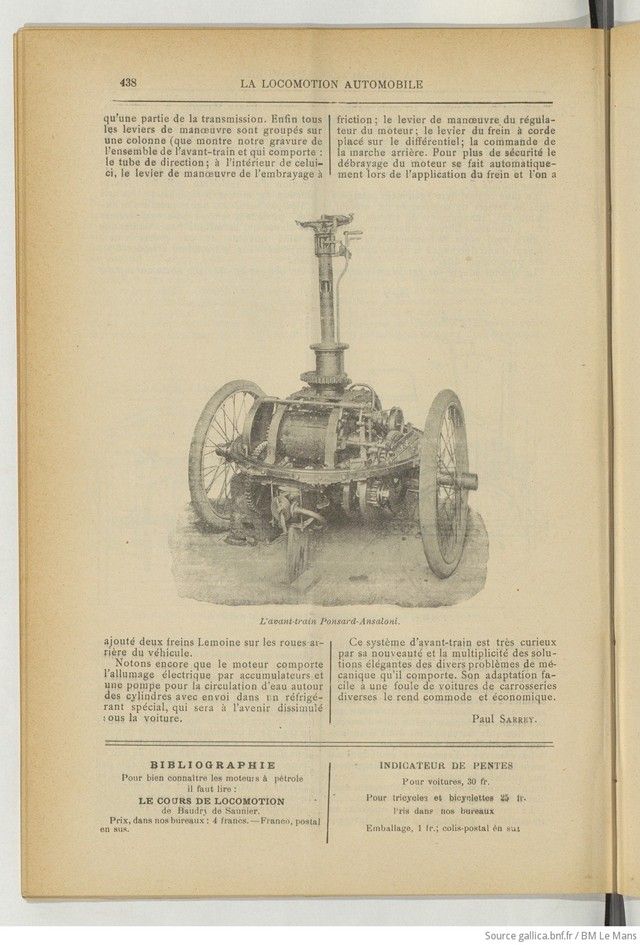

The car on display was a French cab of the type used by the Compagnie Générale des Voitures in Paris. The original model has recently been improved in terms of its external appearance by two minor changes that nevertheless give the overall design a lighter look. The engine will now be reversed, i.e., positioned towards the rear of the front axle, which will partially conceal it from view, along with part of the transmission. Finally, all the control levers are grouped together on a column (shown in our engraving of the front end assembly), which includes: the steering tube; inside it, the friction clutch control lever; the engine regulator control lever; the cable brake lever on the differential; and the reverse gear control. For added safety, the engine is automatically disengaged when the brake is applied, and two Lemoine brakes have been added to the rear wheels of the vehicle.

It should also be noted that the engine features electric ignition via batteries and a pump for circulating water around the cylinders, which is sent to a special cooling system that will in future be concealed under the car.

This front-wheel drive system is very interesting due to its novelty and the multitude of elegant solutions it offers to various mechanical problems. Its easy adaptation to a wide range of cars with different body styles makes it convenient and economical.

Paul Sarrey.

Photos.

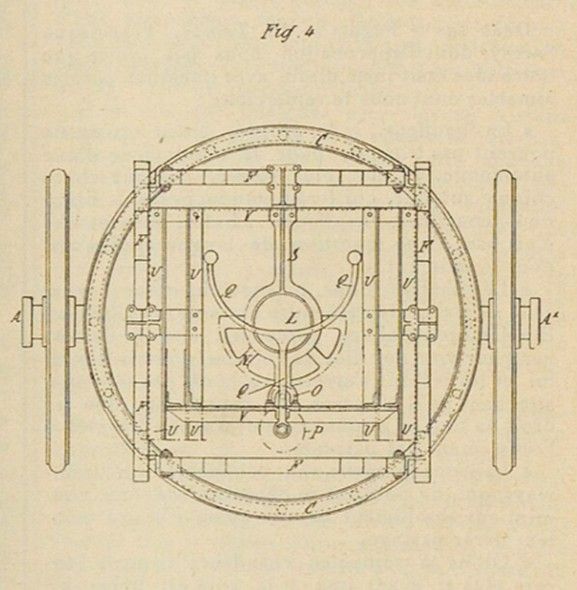

Fig. 1 (Fig. 4) Details of the Ponsard-Ansaloni front-wheel drive transmission and steering system.

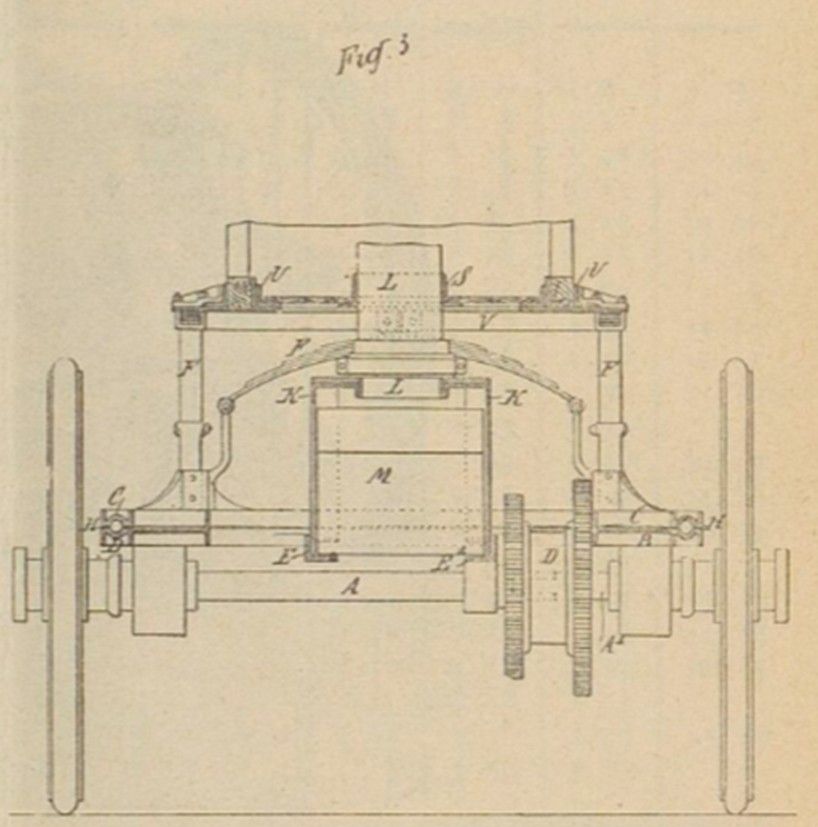

Fig. 2 (Fig. 3) Profile and end view of the Ponsard-Ansaloni front-wheel drive system. The Ponsard-Ansaloni front-wheel drive system.