Text and jpegs by courtesy of hathitrust.org www.hathitrust.org, compiled by motorracinghistory.com

Motor Age, Vol. LIII (53), No. 12, March 22 1928

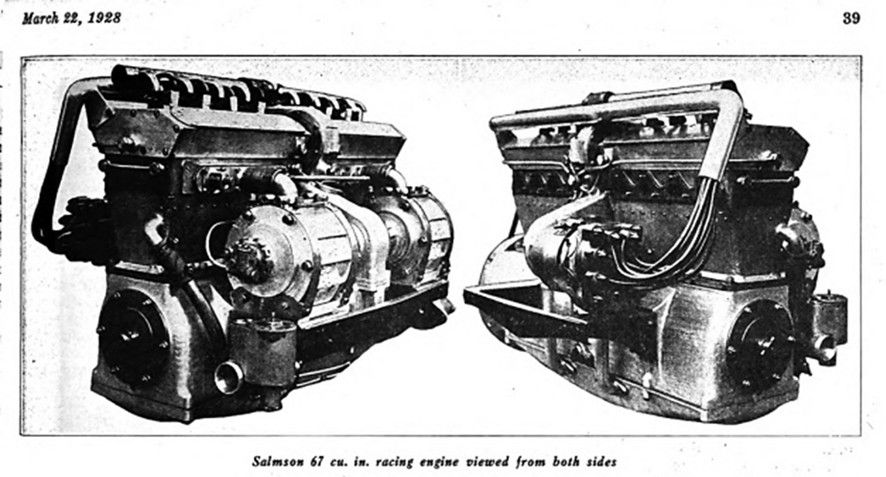

67 Cu. In. Straight-Eight Racing Engine Built by Salmson

Built by Salmson of Paris, Develops 100 hp. at 5800 r.p.m. and Will Turn Up to 8000 r.p.m. – Gives Car a Speed of About 125 m.p.h.

By W. F. Bradley (Motor Age European Correspondent)

SUPERCHARGED straight-eight racing engines of only 67 cu. in. piston displacement have been produced by the Salmson Automobile Co. of Paris and will be used in European track and road races during the coming year.

Salmson specializes in the production of stock cars of about 67 cu. in. displacement and for several years has been very prominent in racing events with cars of this size having a certain resemblance to the stock product. It is realized that the four-cylinder engine has reached the limit of its development, and the eight-cylinder models from designs of Engineer Petit, are intended to replace them.

Although no definite statement regarding output has been made, it is known that the engine has shown 100 hp. at 5800 r.p.m. and that it will turn up to 8000 r.p.m. The speed of the cars is believed to be in the neighborhood of 125 m.p.h. The cylinders, which have a bore and stroke of 49.9 by 70 mm. (1.95 by 2.75 in.), are in two castings of four, with a detachable cast-iron head, carrying two valves per cylinder at an angle of 30 deg. from the vertical. The iron water jackets are cut away and replaced by sheet steel riveted jackets. The cylinder blocks are mounted on a barrel shaped aluminum crankcase to which an aluminum oil sump is attached.

The feature of this engine is the method of treating it as a double four, with the timing gear in the center and the accessories mounted symmetrically to left and right of this gear. The crankshaft is in two forgings, with a keyed taper joint between them, over which the accessories drive pinion is keyed.

This arrangement of a certain drive not only tends to minimize the effect of torsional vibration on the gears, but it has the further advantage of providing the maximum degree of accessibility for the various parts. The crankshaft is carried in ball bearings at both ends and also at each side of the central joint, while roller bearings are used between cylinders Nos. 2 and 3 and Nos. 6 and 7. The connecting rods are mounted on the shaft with roller bearings. The pistons are magnesium forgings carrying three compression rings and one scraper ring.

A train of spur pinions drives the overhead camshafts. By reason of the arrangement of two separate blocks of cylinders and central drive, each camshaft is in two parts, with an elastic coupling allowing for a slight amount of relative movement. Either half can be dismounted without disturbing the other.

The camshafts operate the valves through inverted steel pistons moving in bronze guides in the camshaft housing, thus eliminating all side thrust on the valve stems. These pistons are positively returned by means of cams on the shaft; thus the valve springs merely have to assure the seating of the valve, without having any of the load of the follower imposed on them. The four housings containing the valve gear are accessibly placed and can be separately dismounted.

Mounted on the right-hand crankcase hangers are two Cozette blowers, the left-hand one delivering mixture to the four forward cylinders and the right-hand one to the rear group. At present the blowers run at slightly less than engine speed, but the design has been laid out so that the speed ratio can be readily changed.

The carburetors are also Cozette make, each one being placed in an accessible position to one side of the blower and connected up to the blower intake, which is on the under face of the aluminum casting. The intake manifold is integral with the cylinders, and, of course, separate for the two blocks, although connected by a by-pass forming an equalizer. There is a pressure relief valve on each manifold. Gasoline is fed to a gravity tank on the cowl by pressure from the blowers.

Immediately under the blower pinion is the water pump, which delivers water to the lowest point at the outer ends of the cylinder blocks. The flow is then upward and toward the center with an outlet from each cylinder to a common collector connecting to the radiator. Lubrication is of the dry sump type.

The magneto is manufactured by the Salmson company. It supplies current to eight plugs mounted vertically in the cylinder head. Provision is made for driving a distributor off the left-hand side of the magneto pinion shaft, if generator and battery ignition is used. Up to the present the engine has run on a magneto only.

To insulate the engine against weaving of the side frame members, a special type of two-point attachment has been adopted. There are two crankcase hangers on each side of the aluminum casting, and to each of these is bolted a forged bracket. The two brackets on each side are united by an inverted L-section side rail, which latter is carried on the chassis side rails and secured to them by two central bolts. The arrangement gives all the advantages of a complete three-point support sub-frame with considerably less weight. The chassis side rails are channel section, with ash filling.

Engine, clutch and transmission form a unit mounted in a chassis showing no great departure from standard practice. Single seater bodies are fitted, these being barrel-shaped and inclosing the driveshaft, shock absorbers and rear axle. They have internal hoops giving sufficient rigidity to protect the driver in case the car rolls over. Whether a differential is fitted depends upon the nature of the race in which the car takes part.

Photo. Salmson 67 cu. in. racing engine viewed from both sides