This article in the Austrian magazine „Allgemeine Automobil=Zeitung“, directly refers to the two-weeks earlier published article in the French article of Henri Gaillard in „La Locomotion Automobile“. It shows that indeed, severaly European magazines cooperated in some respect.

Text and images with authorisation of anno.ac.at / Österreichische Nationalbibliothek, compiled by motorracinghistory.com, Translation by DeepL.com

Allgemeine Automobil-Zeitung, Volume VII, Band. II, Nr. 28, Juli 25, 1906

Two-piece and removable rims.

By Henri Gaillard in „La Locomotion Automobile“

In the issue of “La Locomotion Automobile” published after the Grand Prix, we find an article by M. Henri Gaillard on the now highly topical subject of removable rims. However, the article appears to have been written before the Grand Prix, as the author makes no reference to the success of removable rims in this race. The following translation of M. Gaillard’s article will certainly be a welcome addition to our readers‘ understanding of the two-piece rim, which was discussed in the last issue of “A. A. Z.” We would also like to note that in French, the two-piece rim is referred to as the jante démontable and the removable rim as the jante amovible.

*

Since the invention of the pneumatic tire, its low resistance has been a serious obstacle, requiring constant repairs to defects caused by a nail or even a sharp stone in the inner tube. This battle, first fought by cyclists and then by motorists, has been going on for years: the battle against pneumatic tire punctures.

It soon became apparent that repairs carried out in a hurry on the road were inadequate, that it was insufficient to try to repair a hole or a tear with a hastily applied patch.

While this was still possible with a light two-wheeler, the heavy weight of a car and the extraordinary tears that occur in pneumatic tires make such attempts at repair so illusory that they were only resorted to in extreme cases. This led to the practice of carrying a sufficient number of inner tubes and even spare tires in order to replace the defective ones and have them repaired later by a specialist in a workshop. As long as you carry spare tires with you, a tire failure is not irreparable, insofar as you can continue driving with the replaced tires; but it still exists, because the operation of replacing a tire or even just an inner tube is difficult and cumbersome enough to cause a fairly long forced stop. Some experienced drivers proudly report that they can perform this operation in less than a quarter of an hour, but these are exceptions that still need to be confirmed. If you ask the average motorist, they will reply that it takes them 25 minutes to replace an inner tube alone, but if the tire also needs to be replaced at the same time, it takes a good three quarters of an hour, assuming they haven’t done something wrong and have to start all over again.

The inventors‘ efforts have therefore always been focused on finding ways to shorten the repair time and thus also the unpleasant delay in travel. The proposed solutions are based on two principles: the two-piece rim and the removable rim. The former has been in use for years and has proven its worth. The removable rim has also been known for some time, but like everything else, it was met with mistrust. It was the Grand Prix that brought about the change.

The two-piece rim.

The difficulty in mounting a tire stems from the fact that the two beads of the tire must be pulled over the outer rim edge, whose diameter is not only significantly larger than that of the inner rim section facing the hub, but also larger than the inner diameter of the beads in their normal state. The tire can therefore only be pulled over the rim as a result of its own elasticity and with considerable effort.

If the outer rim of the rim were not there at all, or at least not at that moment, the operation would be considerably simplified. This is now the case with the two-piece rim, which, as the name suggests, consists of two parts, one of which, forming the outer rim, can be removed and, once mounting is complete, can be wedged or bolted back into place.

These two-piece rim systems, as interesting and ingenious as they may be, have the overall disadvantage that they require the individual parts to fit together precisely and that the whole thing is still a relatively fragile apparatus, especially when you consider that in the event of a tire blowout, for example, a car traveling at high speed often has to drive on the bare rim for a considerable amount of time. The result is deformation not only of the bolts or wedges, but of the entire rim edge, which directly calls into question its further usability.

Furthermore, from the point of view of repairing the breakdown, the two-piece rim offers only an incomplete solution. Replacing a tire is not the only inconvenience with this type of breakdown; inflating the inner tube is also hard work, especially in the heat of the sun and with a pump that is not completely airtight, not to mention the inconvenience of getting dirty and smeared with dust, grease, etc. However, it must be acknowledged that the two-piece rim saves a considerable amount of time when it comes to mounting a tire.

The removable rim.

With the removable rim, the question of mounting or removing the tire from the rim no longer arises; you simply leave the defective tire on the rim as it is, remove the rim completely, replace it with a new one with a fresh tire, and can continue driving without the whole operation taking more than a few minutes. Speed is not rocket science.

This is certainly an extraordinary advance, and if practice lives up to theory, the invention has every right to the highest sympathy of the chauffeur corps. In practice, however, certain difficulties remain to be solved.

1. The tire must be mounted on its metal rim just as solidly and securely as it is on a conventional spoked wheel.

2. The metal rim must fit into the wooden rim of the spoked wheel without any difficulty.

3. The connection between the removable rim (which we will refer to as the pneumatic rim for the sake of clarity) and the wooden spoked wheel must be so secure that any lateral movement of the former on the latter, as well as any sliding in the direction of rotation, is absolutely impossible.

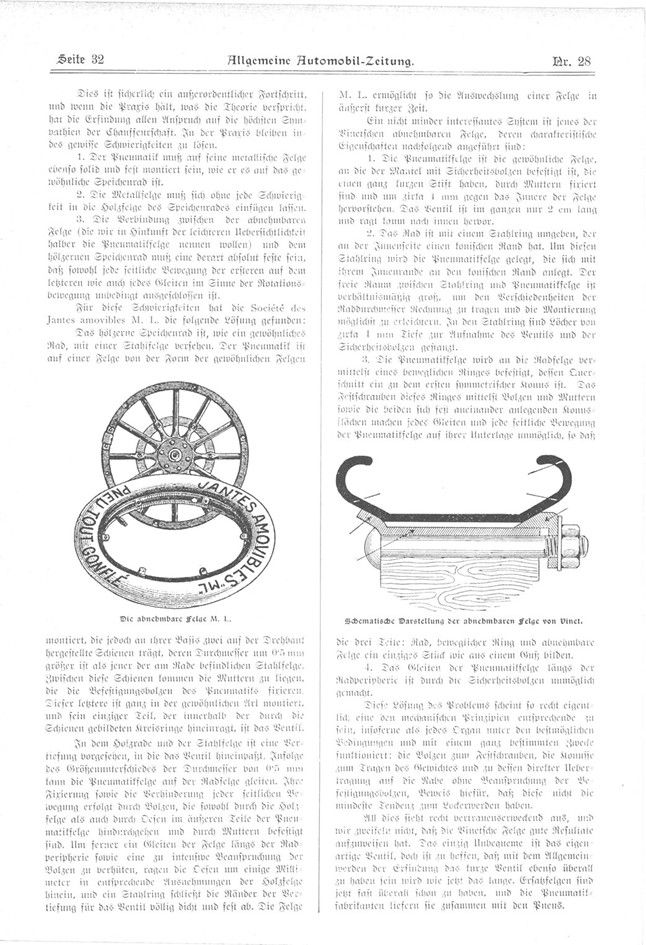

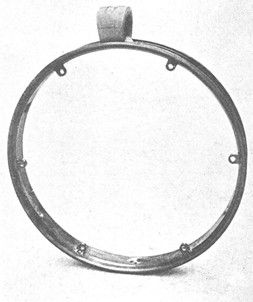

The Société des jantes amovibles M. L. has found the following solution to these difficulties:

The wooden spoked wheel is fitted with a steel rim, just like a normal wheel. The pneumatic tire is mounted on a rim of the same shape as ordinary rims, but with two lathe-made rails at its base, the diameter of which is 0.5 mm larger than that of the steel rim at the edge. The nuts that secure the tyre’s mounting bolts are placed between these rails. The tyre is mounted in the usual way, and the only part that protrudes inside the circular rings formed by the rails is the valve.

There is a recess in the wooden wheel and the steel rim into which the valve fits. Due to the difference in diameter of 0.5 mm, the pneumatic rim can slide on the wheel rim. It is secured and prevented from moving sideways by bolts that pass through both the wooden rim and bolt eyelets in the outer parts of the pneumatic rim and are fastened with nuts. To further prevent the rim from sliding along the wheel periphery and excessive stress on the bolts, the eyelets protrude a few millimeters into corresponding recesses in the wooden rim, and a steel ring completely seals the edges of the recess for the valve. The M. L. rim thus allows a rim to be replaced in a very short time.

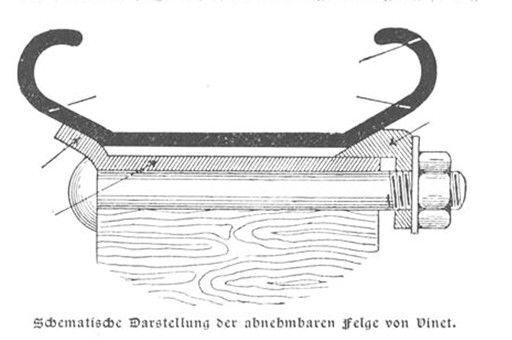

A no less interesting system is that of Vinetschen’s removable rim, whose characteristic features are listed below:

1. The pneumatic rim is a conventional rim to which the tire is attached with safety bolts that have a very short pin, are secured with nuts, and protrude approximately 4 mm below the rim. The valve is only 2 mm long in total and hardly protrudes inwards.

2. The wheel is surrounded by a steel ring with a conical edge on the inside. The pneumatic rim is placed around this steel ring, with its inner edge resting against the conical edge.

The free space between the steel ring and the pneumatic rim is relatively large in order to accommodate the differences in wheel diameter and to make assembly as easy as possible. Holes approximately 4 mm deep are punched into the steel ring to accommodate the valve and the safety bolts.

3. The pneumatic rim is attached to the wheel rim by means of a movable ring whose cross-section is symmetrical to the first cone. The tightening of this ring by means of bolts and nuts, as well as the two cone surfaces that fit tightly together, make any lateral movement of the pneumatic rim on its base impossible, so that the three parts: wheel, movable ring, and removable rim form a single piece as if cast from a mold.

4. The safety bolts prevent the pneumatic rim from sliding along the wheel periphery.

This solution to the problem seems to be in line with mechanical principles, insofar as each component functions under the best possible conditions and with a specific purpose: the bolts for fastening, the cones for bearing the weight and transferring it directly to the hub without straining the fastening bolts, proof that these have no tendency to come loose.

All this looks very promising, and we have no doubt that the Vinetsche rim will produce good results. The only inconvenience is the peculiar valve, but it is to be hoped that as the invention becomes more widespread, the short valve will be as widely available as the long one is now. Replacement rims are now available almost everywhere, and tire manufacturers supply them together with the tires.

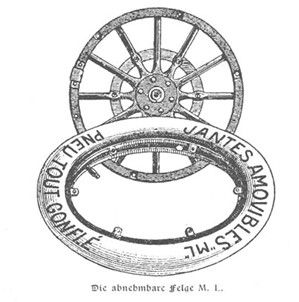

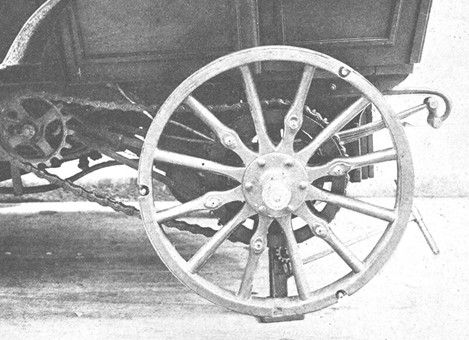

The removable rim M. L.

Here are two more illustrations of the removable rim M. L. Of the two illustrations shown here, the upper one shows the removable rim before the tire has been mounted and inflated. You can see the six eyelets through which the fixing nuts are inserted. The image below illustrates how the “jante amovible M. L.” is attached to a car wheel. The removable rim, in both versions produced by the “Société des jantes amovibles M. L.” and by the company Vinet, represents a step forward compared to the two-piece rim systems that have been known and in use for years. With the removable rim, the driver is spared the trouble of mounting and dismounting the pneumatic tire; the defective tire is simply left on the rim and a new rim with the pneumatic tire already mounted is attached to the wheel. We would like to take this opportunity to mention that the removable rim M. L. Austria-Hungary is represented by the company J. König, Vienna, II. Große Mohrengasse 25.

Photo captions.

Page 32. The removable rim M. L. – Schematic representation of the removable rim from Vinet.