In this october 1929 issue of the French automotive magazine Omnia, front wheel drive is discussed. Based on what happened till then in the United States on this subject, the French technical press looks into some new concepts. Examples of both the Auburn and the Cord car first are briefly highlighted, followed by the new design of the Hungarian designer Béla Barényi. In this very futuristic design, at least for those days, the engine is the only classic component. But for the rest, the advantages of front wheel drive are applied and used to their maximum.

With authorisation of Bibliothèque national francais, gallica.bnf.fr.

Text and photos compiled by motorracingistory.com., Translation by DeepL.com

Omnia – Salon, Revue pratique de l’Automobile, Vol. 23, No. 113, October 1929

TRENDS AND PROGRESS IN AUTOMOBILE MANUFACTURING 1930

VI. — FRONT-WHEEL DRIVE

by A. CAPUTO.

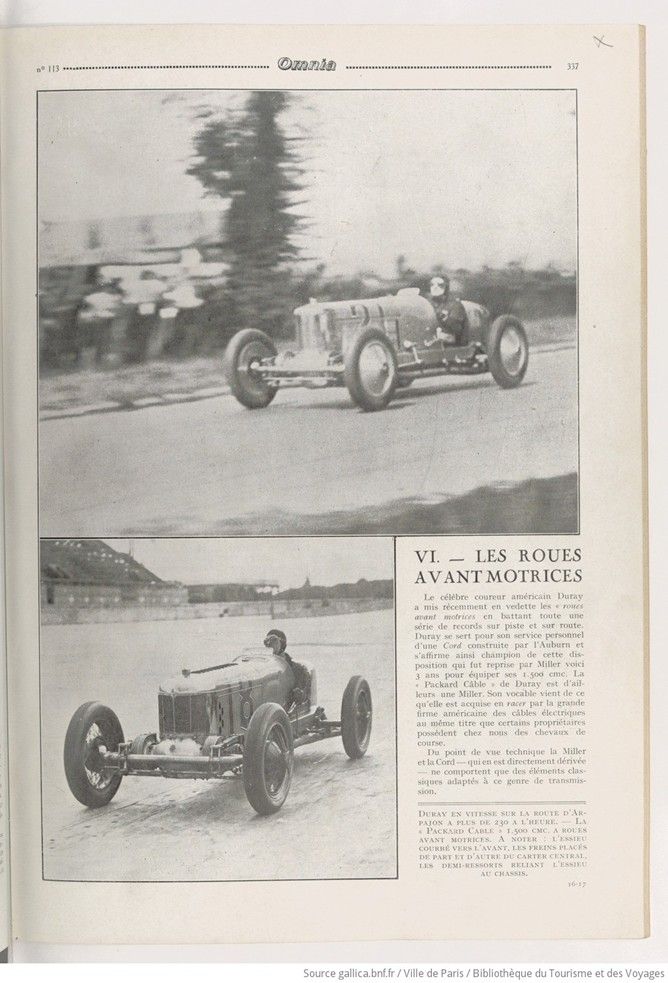

The famous American racer Duray recently showcased front-wheel drive by breaking a whole series of records on the track and on the road. Duray uses a Cord built by Auburn for his personal use, thus confirming himself as the champion of this design, which was adopted by Miller three years ago to equip its 1,500 cc cars. Duray’s Packard Cable is actually a Miller. Its name comes from the fact that it was acquired as a racer by the large American electrical cable company, in the same way that some owners in our country own racehorses.

From a technical point of view, the Miller and the Cord — which is directly derived from it — only feature conventional components suitable for this type of transmission.

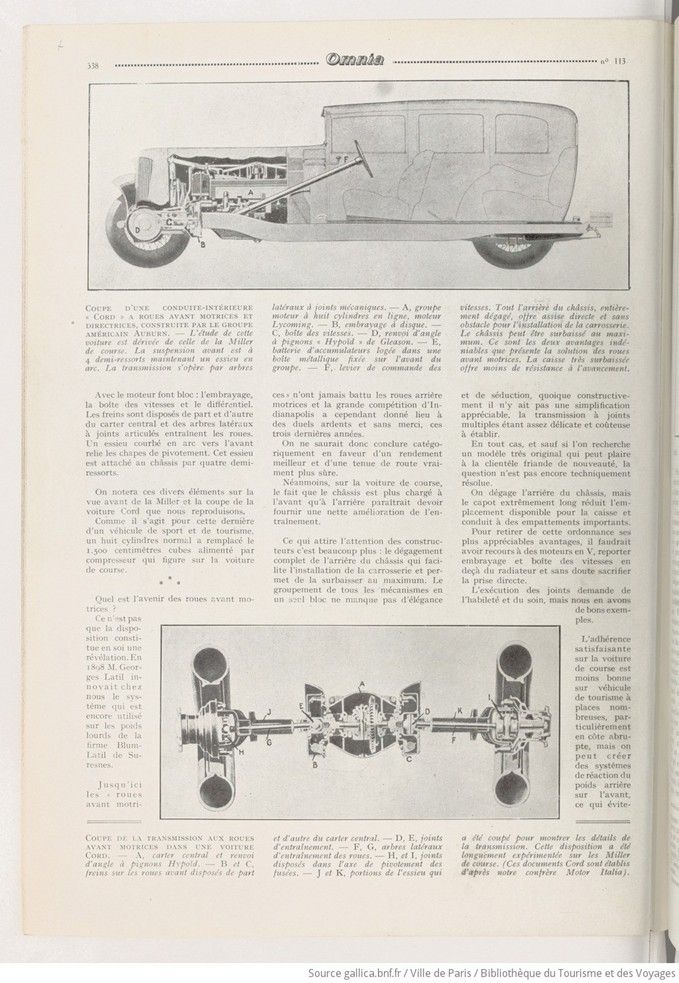

The engine is integrated with the clutch, gearbox, and differential. The brakes are located on either side of the central housing, and the side shafts with articulated joints drive the wheels. A forward-curving axle connects the pivot caps. This axle is attached to the chassis by four half-springs.

These various elements can be seen in the front view of the Miller and the cross-section of the Cord car that we reproduce here.

As the latter is a sports and touring car, a standard eight-cylinder engine has replaced the 1,500 cc supercharged engine found in the racing car.

* * *

What is the future of front-wheel drive?

It is not that the layout itself is a revelation. In 1898, Mr. Georges Latil pioneered the system that is still used on the heavy trucks of the Blum-Latil company in Suresnes.

Until now, front-wheel drive has never beaten rear-wheel drive, and yet the Indianapolis Grand Prix has seen some fierce and relentless battles over the last three years.

It is therefore impossible to conclude categorically that it offers better performance and truly safer handling.

Nevertheless, on a race car, the fact that the chassis is heavier at the front than at the rear would seem to provide a clear improvement in traction.

What attracts the attention of manufacturers is much more the complete clearance of the rear of the chassis, which facilitates the installation of the bodywork and allows it to be lowered as much as possible. The grouping of all the mechanisms into a single block is elegant and attractive, although in terms of construction there is no significant simplification, as the multi-joint transmission is quite delicate and costly to build.

In any case, unless you are looking for a highly original model that will appeal to customers who love novelty, the issue has not yet been technically resolved.

The rear of the chassis is cleared, but the extremely long hood reduces the space available for the body and leads to long wheelbases.

To reap the most significant benefits of this layout, V engines would have to be used, the clutch and gearbox would have to be moved behind the radiator, and direct drive would undoubtedly have to be sacrificed.

The joints require skill and care to execute, but we have some good examples.

The satisfactory grip on a race car is not as good on a passenger vehicle with many seats, particularly on steep hills, but rear weight reaction systems can be created for the front, which would avoid this pitfall if it is found to be a problem.

In order to achieve a well-balanced and perfectly centered front-wheel drive car, a great deal of fine-tuning is therefore required.

The very interesting studies conducted on certain types of sports cars will shed light on the problem. If front-wheel drive is combined with independent wheels, new stability qualities are acquired. In order to fully determine the relative importance of the factors involved, comparative experiments should be carried out, which, to our knowledge, have never been attempted. We make this remark because it would be easy to attribute to one factor what is almost entirely due to the other, especially since we are then influenced by the independent front wheels and not the four independent wheels.

However, it is the independence of the front wheels that is crucial to the problem of stability.

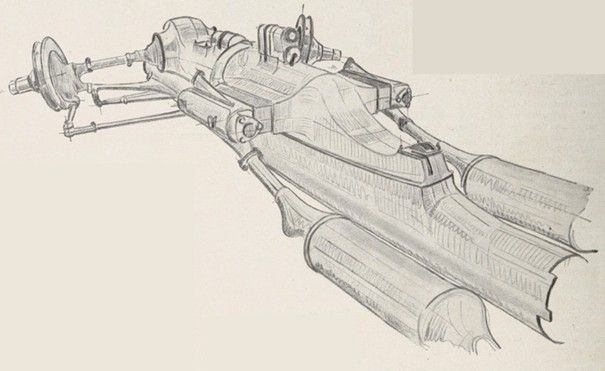

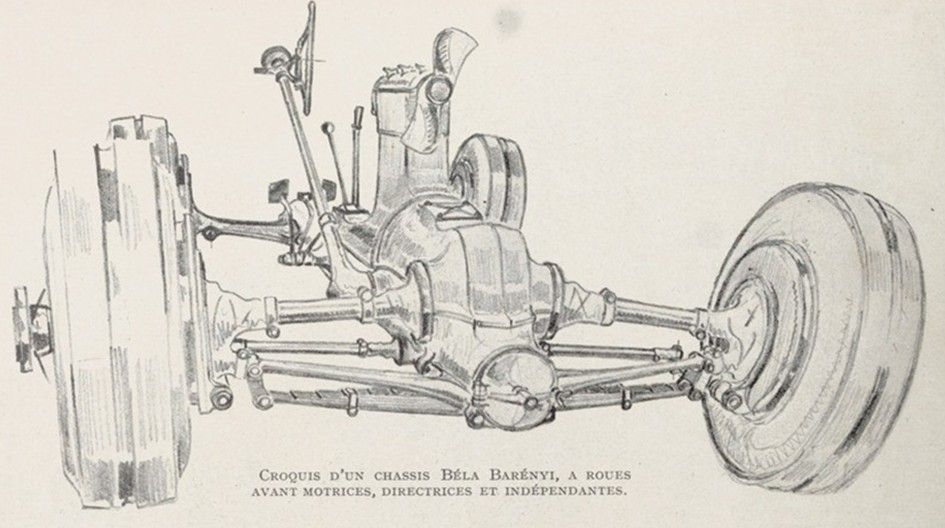

One of our kind correspondents at Omnia, Mr. Béla Barényi of Vienna, has kindly sent us some very elegant and highly original sketches that suggest entirely new applications for front-wheel drive.

Except for the engine block, the design of the mechanisms is no longer conventional.

A central beam serves as the chassis frame.

There are no longer any axles, but instead articulated lever assemblies. The suspension springs are transverse, with one spring for each axle.

Strong cross members attached to the central tube form the body mountings.

The entire engine and transmission assembly is a single unit at the front, housed in a bowl-shaped compartment: a direct extension of the central tube.

Many ancillary parts and joints have been eliminated. The central beam does not experience any significant distortion and the bodywork will not be subject to any twisting forces that could dislocate it.

This saves metal, labor, and assembly time. The result is a lighter vehicle. There are certainly some promising ideas here for the future.

What we can conclude! Front-wheel drive is set to feature on certain sports cars. It is an original feature and many enthusiasts are drawn to it.

Rear-wheel drive will remain for a long time the preserve of utility vehicles and service cars, for which safety is the primary concern and which must be manufactured for several years in the same unmodified form in order to continuously improve their cost price. This is Ford’s method, and it is the right method.

It is possible to achieve a lowering very close to the practical maximum with the classic rear-wheel drive with a simple, rustic drive axle, which is currently perfectly tuned. The advantages of the drive axle are likely to prove even more valuable than we suppose, once the use of independent front wheels becomes more widespread and we have a new understanding of the stability conditions of the complete vehicle.

Whereas the search to reduce unsprung weight is undoubtedly of great interest for improving suspension, it should nevertheless be borne in mind that connecting the rear wheels by an axle can be a key factor in stability, provided that bouncing and loss of wheel contact with the ground are avoided. The suspension will only be required to absorb shocks caused by road irregularities and will no longer have to resist the complex movements of the unsprung part resulting in particular from the effects of centrifugal force. Special assemblies and components will then be designed for this purpose, and the engine mount will act as a stabilizer.

Experience will teach us lessons. Inevitably, as is only logical, we will see increasingly lighter cars with very powerful and very flexible engines. These lightweight cars may then have four-wheel drive, and everyone will agree.

Photos.

DURAY SPEEDING ALONG THE ARPAJON ROAD AT OVER 230 KM/H. THE “PACKARD CABLE” 1,500 CMC. FRONT-WHEEL DRIVE. NOTE: THE AXLE CURVED FORWARD, THE BRAKES PLACED ON EITHER SIDE OF THE CENTRAL CARTER, AND THE HALF-SPRINGS CONNECTING THE AXLE TO THE CHASSIS.

CROSS-SECTION OF A “CORD” INTERIOR WITH FRONT-WHEEL DRIVE AND STEERING, BUILT BY THE AMERICAN AUBURN GROUP. — The design of this car is derived from that of the Miller racing car. The front suspension consists of four half-springs supporting an arched axle. Power is transmitted by side shafts with mechanical joints. – A, eight-cylinder in-line engine, Lycoming engine . – B, disc clutch. — C, gearbox. – D, Gleason “Hypoid” angular gearbox. – E, battery housed in a metal box attached to the front of the engine. – F, gear shift lever. The entire rear of the chassis is completely unobstructed, providing a direct, unimpeded base for the installation of the bodywork. The chassis can be lowered to its maximum height. These are the two undeniable advantages of front-wheel drive. The very low body offers less resistance to forward motion.

CROSS-SECTION OF THE FRONT-WHEEL DRIVE TRANSMISSION IN A CORD CAR. – A, central housing and hypoid gear angle drive. — B C, front wheel brakes located on either side of the central housing. – D, E, drive joints. – F, G, side drive shafts. – H, and I, joints located in the pivot axis of the steering knuckles. – J and K, sections of the axle that have been cut away to show the details of the transmission. This layout has been extensively tested on Miller racing cars. (These Cord documents are based on information provided by our colleagues at Motor Italia).

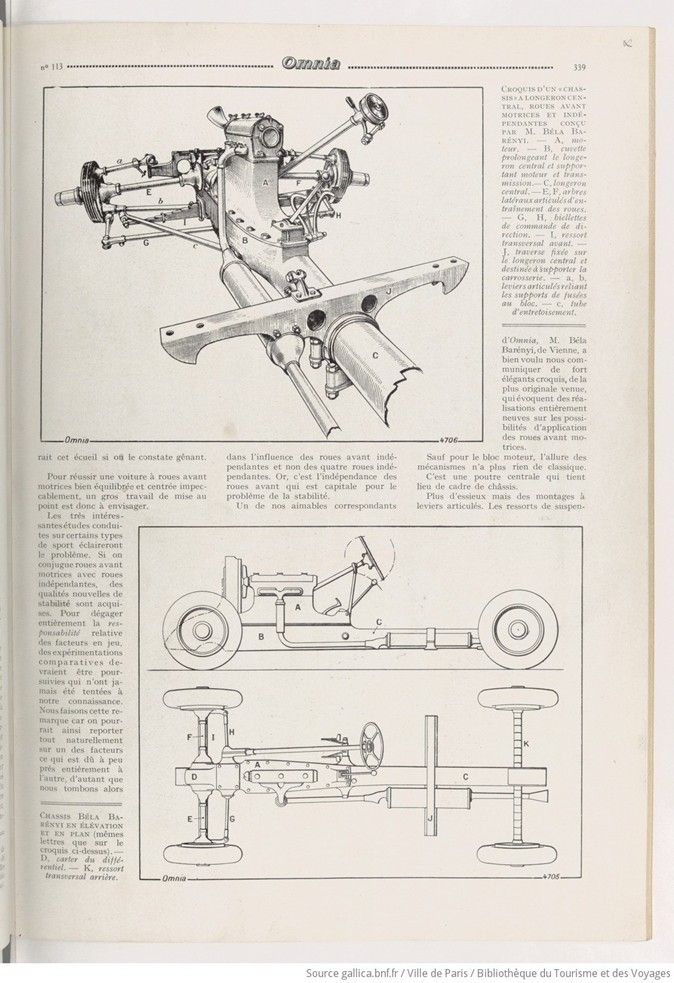

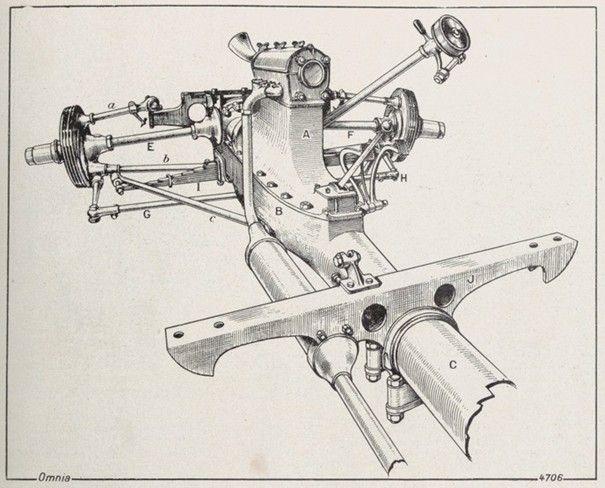

SKETCH OF A CENTRAL LONGITUDINAL BEAM CHASSIS WITH FRONT-WHEEL DRIVE AND INDEPENDENT SUSPENSION DESIGNED BY MR. BÉLA BARÉNYI. – A, engine. – B, cradle extending the central longitudinal beam and supporting the engine and transmission. – C, central longitudinal beam. — E, F, articulated side shafts driving the wheels. — G, H, steering control rods. — 1, front transverse spring. — J, cross member fixed to the central longitudinal member and designed to support the bodywork. — a, b, articulated levers connecting the steering knuckle supports to the block. – c, strut tube.

BÉLA BARÉXYI CHASSIS IN ELEVATION AND PLAN (same letters as in the sketch above). — D, differential housing. – K, rear transverse spring.

SKETCH OF A BÉLA BARÉNYI CHASSIS WITH FRONT-WHEEL DRIVE, STEERING AND INDEPENDENT WHEELS.

SKETCH OF A BÉLA BARÉNYI CHASSIS WITH FRONT-WHEEL DRIVE, STEERING AND INDEPENDENT WHEELS. 8-CYLINDER HORIZONTAL OPPOSITE ENGINE.