With authorisation of the Bibliothèque national francais, gallica.bnf.fr.

Text and jpegs compiled by motorracingistory.com, Translation by DeepL.com

La Locomotion Automobile – Volume 12, N° 25, June 22, 1906.

REMOVABLE RIMS AND DETACHABLE RIMS

Since the invention of the pneumatic tire, we have had to contend with its fragility and repair damage to the tire or inner tube caused by nails or even stones on the road.

For years, cyclists and then drivers have been fighting against tire failure.

It was quickly recognized that makeshift repairs carried out on the road, and patching holes in inner tubes with hastily glued pieces, were futile. While this might be acceptable for bicycles, the weight of cars and the intense heat generated by rolling make such repairs so illusory that they are only used as a last resort. It has therefore become common practice to carry spare inner tubes and even spare tires in sufficient numbers to be able to take the damaged parts back and have them repaired at leisure by specialists.

As long as you have spare parts, the breakdown is not insurmountable, and you can always continue on your way. However, the breakdown still exists, because the operation of changing a tire or even just an inner tube on the road is delicate and complicated enough to require a prolonged stop.

Some highly skilled drivers proudly claim that they can do this in less than a quarter of an hour, but these are exceptional cases that need to be verified. If you ask the majority of motorists, they will honestly say that replacing an inner tube takes 25 minutes and that if the tire also needs to be changed, it takes nearly 45 minutes, not to mention cases where a wrong move means the job has to be done twice.

Inventors have naturally focused their efforts on this aspect and have sought to reduce this time and, consequently, the duration of breakdowns. The proposed solutions are based on two principles: removable rims and detachable rims.

Removable rims. — The difficulty in mounting the tire stems entirely from the fact that it is necessary to get the two beads of the tire over the outer rim, whose diameter is considerably larger than that of its middle section, and even larger than the inner diameter of the beads in their normal state. They can therefore only do so thanks to their relative elasticity and with considerable effort. If the outer rim did not exist, at least temporarily, the operation would be considerably simplified.

The inventors of removable rims recommend two-part rims, one of which, forming the outer rim, can be removed to allow for a clamping or keying system.

There are many devices of this type, including the Peter removable rim, in which the movable part has a rail around its entire inner circumference that fits into a corresponding groove in the fixed part, where it is held in place by a reduction in its diameter using a double-threaded screw.

The “Le Rêve” removable rim seeks to secure the movable rim without screws or nuts, but by means of a key ring that can, at will and by the action of a spring, either disappear completely into the groove of the fixed part, or fit into this groove and a similar groove in the movable rim, thereby locking them securely together.

These solutions to the problem of the two-part rim, however interesting and ingenious they may be, all have the disadvantage of requiring a certain degree of precision in the fitting of their various parts, which makes them rather fragile instruments, especially when one considers that, in the event of a blowout, for example, the car, often traveling at high speed, continues to roll for a considerable time with all its weight on the rim without the cushion provided by the inflated tire. This can result in deformation of the nuts or keys, or even of the rim itself, which will make subsequent operation difficult.

Moreover, even if we consider only the problem of repairing the flat tire itself, the removable rim offers only an incomplete solution: the difficulty of mounting the tire is not the only drawback; there is also the inflation, which is very tiring when you have to operate a pump with questionable airtightness in the hot sun. there is also the significant disadvantage for some refined drivers of getting covered in dust and talcum powder, etc. However, it must be acknowledged that the removable rim saves time, not only on the road but also whenever a tire has to be removed for one reason or another. We will see that the proponents of the removable rim are not concerned about these cases.

The inventors who sought to develop removable rim systems were in a hurry, and for that reason, they deserve the sympathy of drivers, who are in a hurry by profession, by taste, and by habit.

A tire has punctured or burst: the aim is to get back on the road quickly, to get back up to fourth gear as soon as possible, mentally calculating the loss that these few moments represent in terms of average speed.

Repairing the tire: seeing if it is the tire or the inner tube that is at fault, if a nail or a piece of flint caused the damage: all that will come later, at the next stop, when you allow yourself to think about something other than the dozens or hundreds of miles ahead and the possibility of climbing hills at the highest possible speed. — Such is the mentality of the driver on the road. If the tire is faulty, change the whole tire; if it goes faster, change the rim; we would change the wheel if necessary, to save time and if it wasn’t too awkward and heavy to carry spare wheels.

With removable rim wheels, there is no longer any need to worry about removing or refitting the tire on the rim: the damaged tire is left on the rim, where it looks unsightly, but it is the rim that is removed from the wheel and stowed away in the luggage compartment, to be replaced by another rim fitted with a solid, well-inflated tire. The rim is then fixed to the wheel and the journey can continue, after losing only two or three minutes in the whole operation.

This is certainly a great improvement, and if practice matches theory, the removable rim immediately wins the driver’s approval.

In practice, there are several difficulties to be resolved.

1. The tire must be fixed to a metal rim as securely as it is mounted on an ordinary wheel.

2. It must be possible to slide the metal rim onto the wooden rim of the wheel without any difficulty.

3. It is necessary to ensure that the mobile rim (which we will call the pneumatic rim for clarity) and the wheel are absolutely secure in order to avoid lateral play on the one hand and slippage in the direction of rotation on the other.

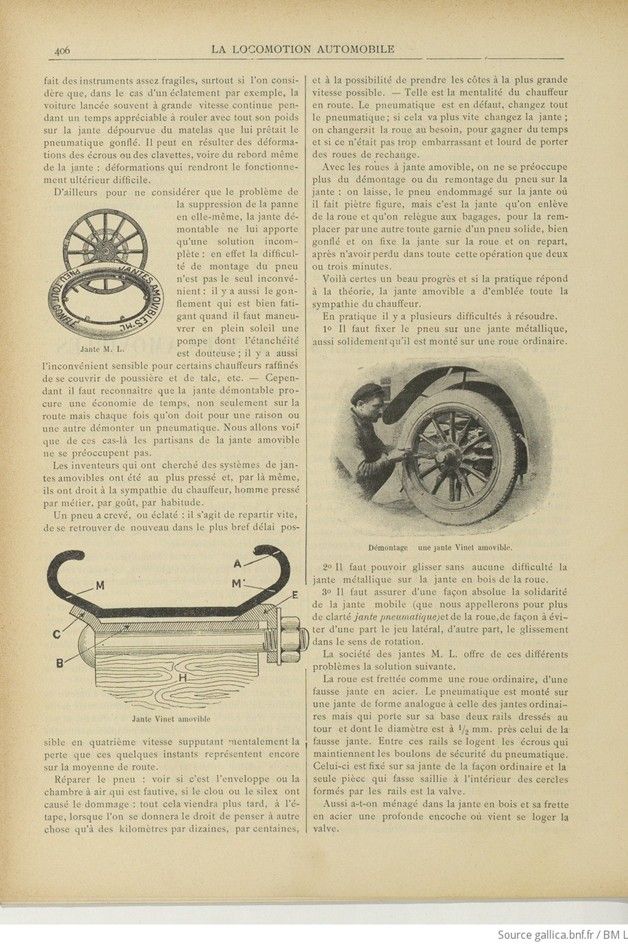

The M. L. Rim Company offers the following solution to these various problems.

The wheel is fitted with a steel false rim in the same way as an ordinary wheel. The pneumatic tire is mounted on a rim similar in shape to ordinary rims but with two lathe-turned rails at its base, the diameter of which is ½ mm, close to that of the false rim. The nuts that hold the tire’s security bolts are located between these rails. The tire is attached to the rim in the usual way, and the only part that protrudes inside the circles formed by the rails is the valve.

A deep notch has therefore been made in the wooden rim and its steel band to accommodate the valve.

The rim can be slid onto the false rim thanks to the difference of 1/2 millimeters between their respective diameters.

The lateral play is fixed and eliminated by bolts that pass through the wooden rim and also pass through lugs riveted to the outer part of the pneumatic rim and are tightened by nuts.

To prevent slippage in the direction of movement and the resulting fatigue on the bolts, the lugs penetrate a few millimeters into recesses in the wooden rim. Finally, a steel piece closes and reinforces the edges of the valve notch.

As it stands, the M. L. rim allows, if all works well, a tire to be changed in a very short time.

Another equally interesting system is the Vinet removable rim.

Here are its characteristics.

1° The pneumatic rim is an ordinary rim such as those found at tire manufacturers. The tire is secured by short-shank safety bolts tightened with nuts, which protrude approximately 4 mm toward the center of the rim. The valve is special because it is 2 centimeters long so that it barely protrudes.

2° The wheel is fitted with a steel band that has a conical rim on the inside. The pneumatic rim slides onto this band until its inner rim rests on the cone. The gap between the pneumatic rim and the false rim is considerable in order to compensate for the differences in diameter that exist on commercially available rims and to make assembly as easy as possible.

The false rim has stamped recesses approximately 4 mm deep, which house the valve and the safety bolts.

3° The pneumatic rim is fixed to the false rim by means of a movable circle whose section forms a symmetrical cone to the first. Tightening the rim with bolts and nuts, and therefore bringing the two cones closer together, eliminates any play that may exist between the pneumatic rim and the false rim, and these three parts—the pneumatic rim, the wheel, and the movable rim—form a single unit.

4° As for slippage in the direction of movement: the safety bolts, which fit tightly into their sockets, are more than sufficient to prevent this.

It seems that we have here a mechanical solution to the problem: because each component acts in the best possible conditions and for a specific purpose: the bolts to achieve tightening; the cones to support the weight and transmit it directly to the hub, without affecting the attachment bolts; the safety bolts to ensure the drive on their own. The proof is that the attachment bolts have no tendency to loosen.

This certainly inspires confidence: and we have no doubt that the removable Vinet rim will give excellent results. The only drawback is the special valve, but it is to be hoped that if this invention becomes widely known, inner tubes with short valves will be as easy to find at stockists as those with long valves, and as for spare rims, they are already widely available as tire manufacturers supply them with tires.

It should be added that mounting the tire on a removable rim is at least as easy as on an ordinary wheel; all you need to do is fit the safety bolts and valve with the appropriate extensions.

Henri Gaillard.

Photo captions. Removable Vinet rim – Removing a removable Vinet rim. – M. L. rim