Text and jpegs by courtesy of hathitrust.org www.hathitrust.org, compiled by motorracinghistory.com

The Automobile, Vol. XXVI (26), No. 24, June 13, 1912

Testing Wheel Strength

Wire, Steel and Hickory Types Tried Out Under Conditions Closely Approaching Road Service

One American Hickory Wheel Superior to One Specimen of Wire and Both Steel Types

THE battle of the wheels is still on. In Europe the wire wheel has the advantage, while in this country the wooden construction still holds the center of the stage. There are adherents to each of these types, as well as those who advocate the general adoption of the sheet steel construction.

In the early days of the automobile in this country the wire wheel was extensively used, but it lost ground, partly through the general opinion that it was unsightly and partly because it is more difficult to keep free from mud and in a presentable condition, due to the net-work of cross wires. These do not loom up as very great objections to its use, and the minute the American public decides that it wants it on its cars, then the wire wheel manufacturer’s problem is solved. It is just as difficult to sell a car in England, especially, which is not equipped with wire wheels as it is in this country to sell one which has any other except wood artillery wheels.

The success of the wire wheel construction in this country, however, depends largely on the showing which it makes within the next few months. Numerous tests are being conducted by more than one of the large manufacturers of automobiles with the object of determining just what the status of the wire construction is in comparison with the wooden types. Up to within a year little has been known of the relative strengths of the various wheel constructions, and it is only now that the engineers are awakening to the possibilities of the wire wheel.

The manufacturers of these wheels have been very consistently advertising them to the American market, which appears to be waiting for more conclusive proofs of their worth.

A very valuable test which should do much to promote the cause of the wire wheel was conducted recently by the pioneers in the wire wheel business, Rudge-Whitworth, Ltd., Coventry, England. This test was designed to show the relative strengths of wire, wood and steel wheels when subjected to the blows from an impact pendulum.

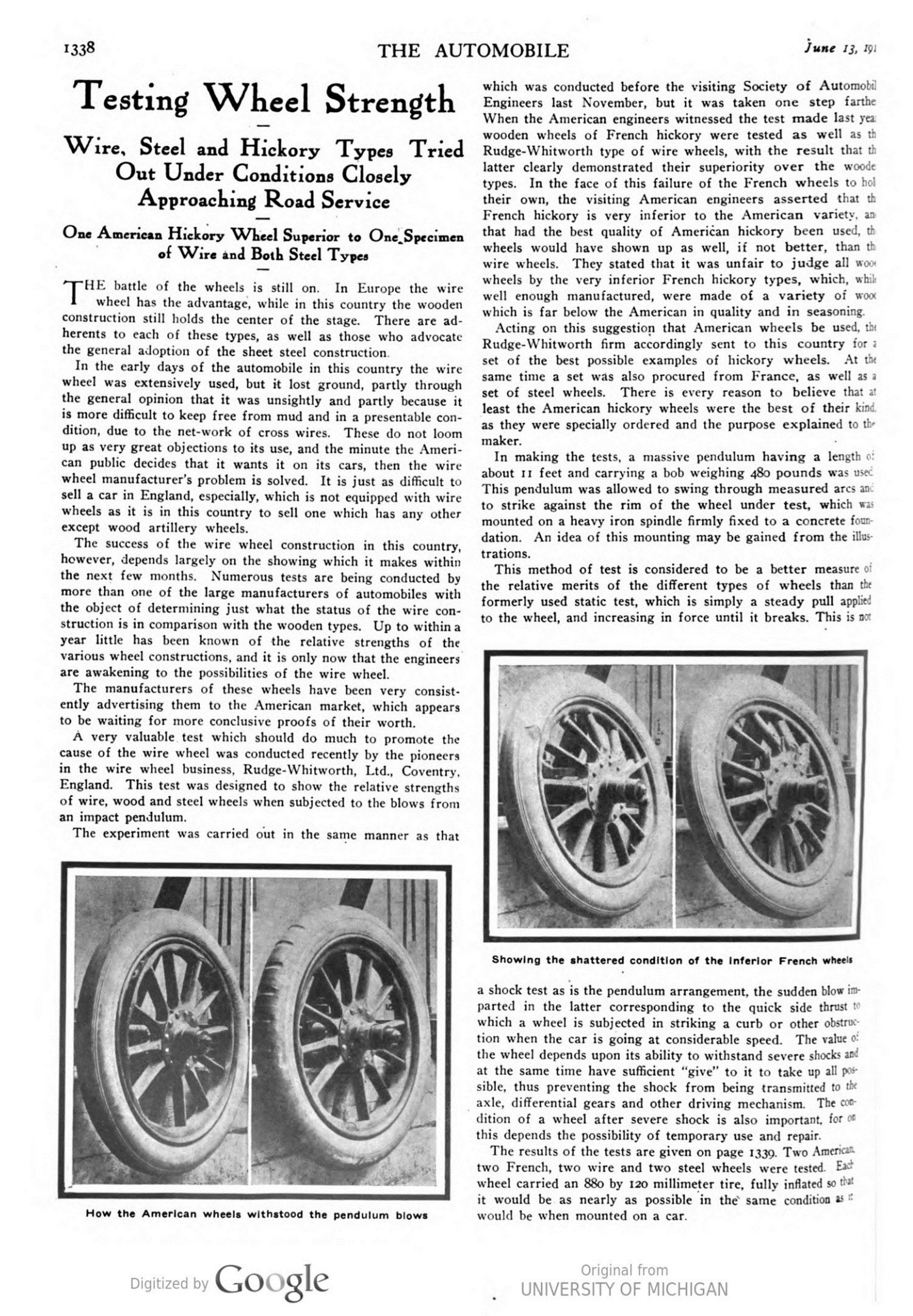

The experiment was carried out in the same manner as that which was conducted before the visiting Society of Automobile Engineers last November, but it was taken one step farther. When the American engineers witnessed the test made last year, wooden wheels of French hickory were tested as well as the Rudge-Whitworth type of wire wheels, with the result that the latter clearly demonstrated their superiority over the wooden types. In the face of this failure of the French wheels to hold their own, the visiting American engineers asserted that the French hickory is very inferior to the American variety, and that had the best quality of American hickory been used, the wheels would have shown up as well, if not better, than the wire wheels. They stated that it was unfair to judge all wood wheels by the very inferior French hickory types, which, while well enough manufactured, were made of a variety of wood which is far below the American in quality and in seasoning.

Acting on this suggestion that American wheels be used, the Rudge-Whitworth firm accordingly sent to this country for a set of the best possible examples of hickory wheels. At the same time a set was also procured from France, as well as a set of steel wheels. There is every reason to believe that at least the American hickory wheels were the best of their kind, as they were specially ordered and the purpose explained to the maker.

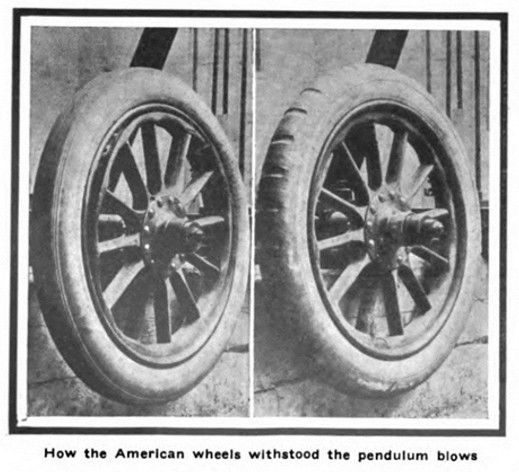

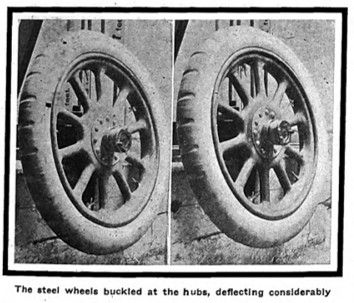

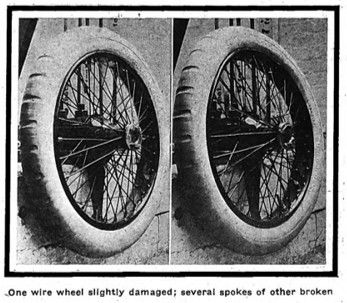

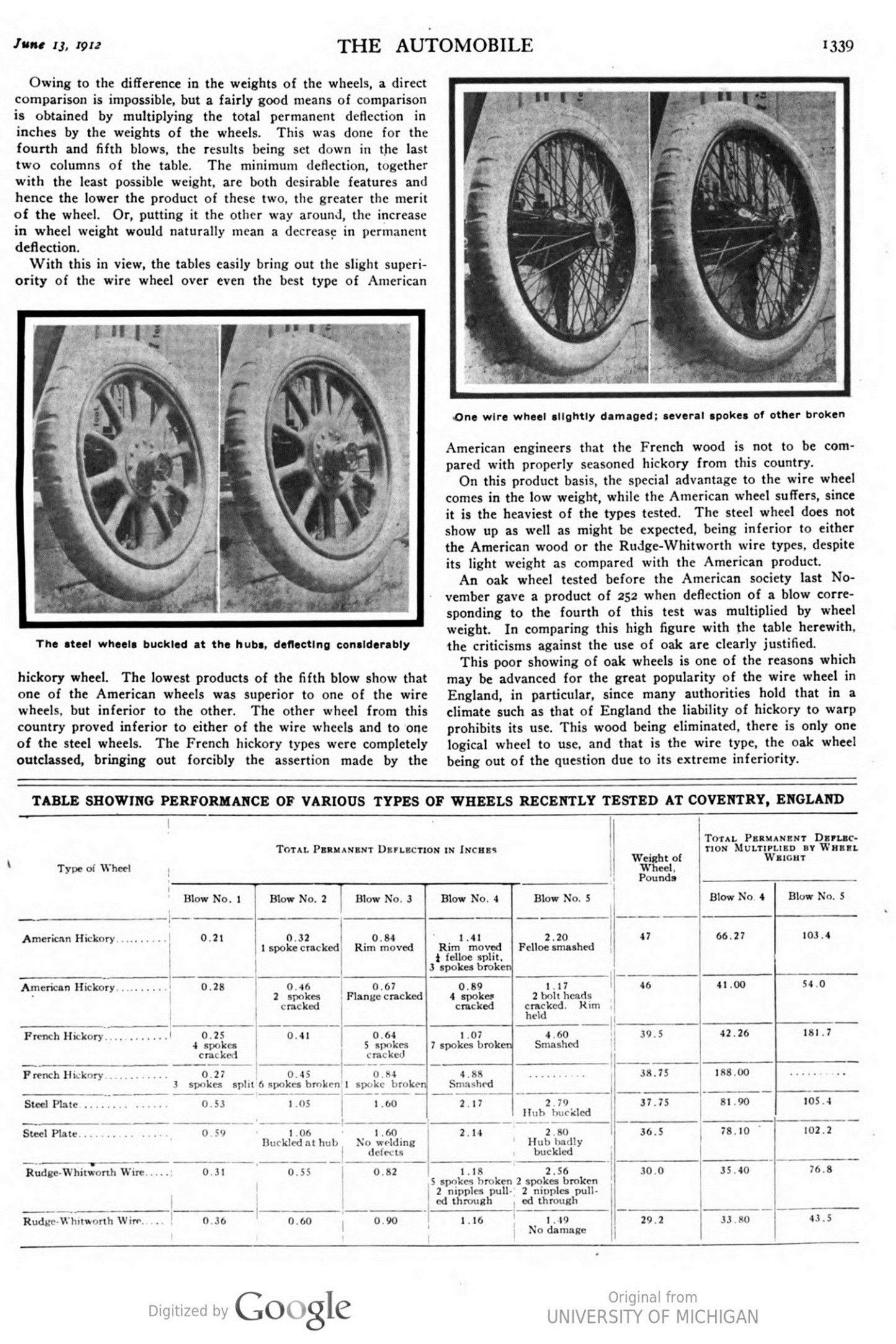

In making the tests, a massive pendulum having a length of about II feet and carrying a bob weighing 480 pounds was used. This pendulum was allowed to swing through measured arcs and to strike against the rim of the wheel under test, which was mounted on a heavy iron spindle firmly fixed to a concrete foundation. An idea of this mounting may be gained from the illustrations.

This method of test is considered to be a better measure of the relative merits of the different types of wheels than the formerly used static test, which is simply a steady pull applied to the wheel, and increasing in force until it breaks. This is not a shock test as is the pendulum arrangement, the sudden blow imparted in the latter corresponding to the quick side thrust to which a wheel is subjected in striking a curb or other obstruction when the car is going at considerable speed. The value of the wheel depends upon its ability to withstand severe shocks and at the same time have sufficient „give“ to it to take up all possible, thus preventing the shock from being transmitted to the axle, differential gears and other driving mechanism. The condition of a wheel after severe shock is also important, for on this depends the possibility of temporary use and repair.

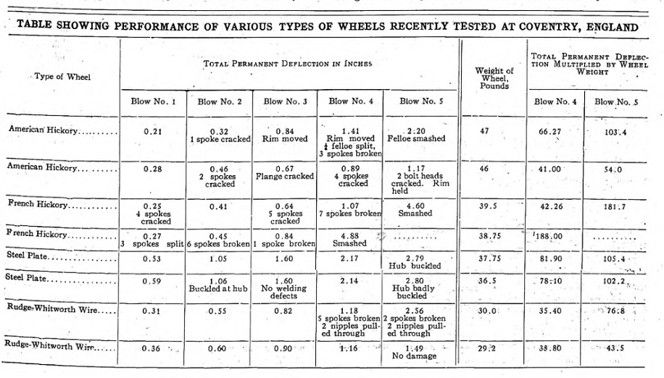

The results of the tests are given on page 1339. Two American, two French, two wire and two steel wheels were tested. Each wheel carried an 880 by 120 millimeters tire, fully inflated so that it would be as nearly as possible in the same condition as it would be when mounted on a car.

Owing to the difference in the weights of the wheels, a direct comparison is impossible, but a fairly good means of comparison is obtained by multiplying the total permanent deflection in inches by the weights of the wheels. This was done for the fourth and fifth blows, the results being set down in the last two columns of the table. The minimum deflection, together with the least possible weight, are both desirable features and hence the lower the product of these two, the greater the merit of the wheel. Or, putting it the other way around, the increase in wheel weight would naturally mean a decrease in permanent deflection.

With this in view, the tables easily bring out the slight superiority of the wire wheel over even the best type of American hickory wheel. The lowest products of the fifth blow show that one of the American wheels was superior to one of the wire wheels, but inferior to the other. The other wheel from this country proved inferior to either of the wire wheels and to one of the steel wheels. The French hickory types were completely outclassed, bringing out forcibly the assertion made by the American engineers that the French wood is not to be compared with properly seasoned hickory from this country.

On this product basis, the special advantage to the wire wheel comes in the low weight, while the American wheel suffers, since it is the heaviest of the types tested. The steel wheel does not show up as well as might be expected, being inferior to either the American wood or the Rudge-Whitworth wire types, despite its light weight as compared with the American product.

An oak wheel tested before the American society last November gave a product of 252 when deflection of a blow corresponding to the fourth of this test was multiplied by wheel weight. In comparing this high figure with the table herewith, the criticisms against the use of oak are clearly justified.

This poor showing of oak wheels is one of the reasons which may be advanced for the great popularity of the wire wheel in England, in particular, since many authorities hold that in a climate such as that of England the liability of hickory to warp prohibits its use. This wood being eliminated, there is only one logical wheel to use, and that is the wire type, the oak wheel being out of the question due to its extreme inferiority.

Note: Elsewhere in this chapter separately, a graphical evaluation and comparison will be given on the results of the different pendulum test that have been performed by the different institutions during this timeframe. GrocerJack.

Photo captions.

Page 1338 + 1339. How the American wheels withstood the pendulum blows – Showing the shattered condition of the Inferior French wheels – The steel wheels buckled at the hubs, deflecting considerably – One wire wheel slightly damaged; several spokes of other broken