Text and jpegs by courtesy of hathitrust.org www.hathitrust.org, compiled by motorracinghistory.com

The Automobile, Vol. XXVI (26), No. 15, April 9, 1914

Steel Wheel Shows Strength in Tests

Withstands Lateral Pressure of 8,940 Pounds to the Square Inch in University of Michigan Trials

DETROIT, MICH., April 7 – The April meeting of the Society of Automobile Engineers brought forth an interesting talk by Max Bachem on some comparative tests of wood, wire and steel wheels as conducted at the Engineering Department of the University of Michigan by F. N. Menefee, civil and hydraulic engineer of that institution.

That the steel wheel is very strong is well enough known, but the data obtained by these tests served to show just what the difference is between the three types. Mr. Bachem, who is representative in this country for the Crown Prince steel wheel, was anxious to obtain accurate data of this nature, and therefore, submitted several of these wheels, together with standard wood and wire types.

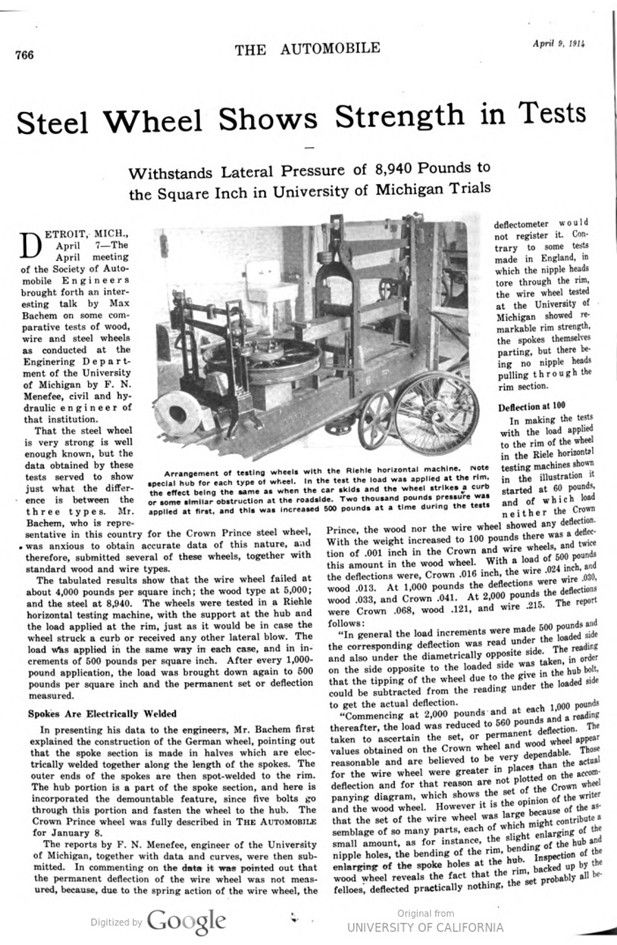

The tabulated results show that the wire wheel failed at about 4,000 pounds per square inch; the wood type at 5,000; and the steel at 8,940. The wheels were tested in a Riehle horizontal testing machine, with the support at the hub and the load applied at the rim, just as it would be in case the wheel struck a curb or received any other lateral blow. The load was applied in the same way in each case, and in increments of 500 pounds per square inch. After every 1,000-pound application, the load was brought down again to 500 pounds per square inch and the permanent set or deflection measured.

Spokes Are Electrically Welded

In presenting his data to the engineers, Mr. Bachem first explained the construction of the German wheel, pointing out that the spoke section is made in halves which are electrically welded together along the length of the spokes. The outer ends of the spokes are then spot-welded to the rim. The hub portion is a part of the spoke section, and here is incorporated the demountable feature, since five bolts go through this portion and fasten the wheel to the hub. The Crown Prince wheel was fully described in THE AUTOMOBILE for January 8.

The reports by F. N. Menefee, engineer of the University of Michigan, together with data and curves, were then submitted. In commenting on the data it was pointed out that the permanent deflection of the wire wheel was not measured, because, due to the spring action of the wire wheel, the deflectometer would not register it. Contrary to some tests made in England, in which the nipple heads tore through the rim, the wire wheel tested at the University of Michigan showed remarkable rim strength, the spokes themselves parting, but there being no nipple heads pulling through the rim section.

Deflection at 100

In making the tests with the load applied to the rim of the wheel in the Riele horizontal testing machines shown in the illustration it started at 60 pounds, and of which load neither the Crown Prince, the wood nor the wire wheel showed any deflection. With the weight increased to 100 pounds there was a deflection of .001 inch in the Crown and wire wheels, and twice this amount in the wood wheel. With a load of 500 pounds the deflections were, Crown .016 inch, the wire .024 inch, and wood .013. At 1,000 pounds the deflections were wire .030, wood .033, and Crown .041. At 2,000 pounds the deflections were Crown .068, wood .121, and wire .215.

The report follows:

„In general the load increments were made 500 pounds and the corresponding deflection was read under the loaded side and also under the diametrically opposite side. The reading on the side opposite to the loaded side was taken, in order that the tipping of the wheel due to the give in the hub bolt, could be subtracted from the reading under the loaded side to get the actual deflection.

„Commencing at 2,000 pounds and at each 1,000 pounds thereafter, the load was reduced to 560 pounds and a reading taken to ascertain the set, or permanent deflection. The values obtained on the Crown wheel and wood wheel appear reasonable and are believed to be very dependable. Those for the wire wheel were greater in places than the actual deflection and for that reason are not plotted on the accompanying diagram, which shows the set of the Crown wheel and the wood wheel. However it is the opinion of the writer that the set of the wire wheel was large because of the assemblage of so many parts, each of which might contribute a small amount, as for instance, the slight enlarging of the nipple holes, the bending of the rim, bending of the hub and enlarging of the spoke holes at the hub. Inspection of the wood wheel reveals the fact that the rim, backed up by the felloes, deflected practically nothing, the set probably all being in the spoke at its junction with the hub and the felloe.

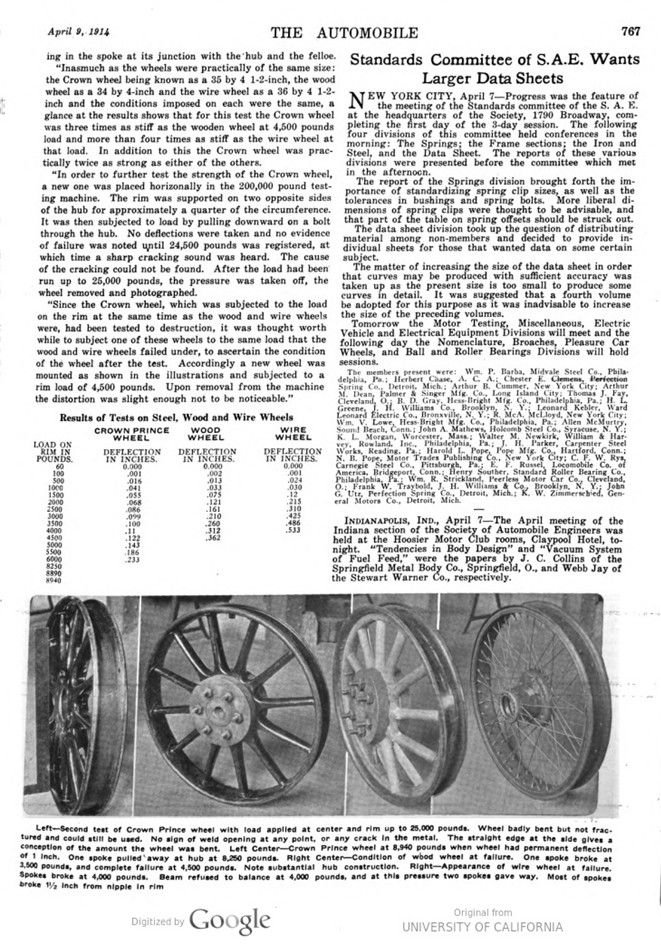

„Inasmuch as the wheels were practically of the same size: the Crown wheel being known as a 35 by 4 1-2-inch, the wood wheel as a 34 by 4-inch and the wire wheel as a 36 by 4 1-2- inch and the conditions imposed on each were the same, a glance at the results shows that for this test the Crown wheel was three times as stiff as the wooden wheel at 4,500 pounds load and more than four times as stiff as the wire wheel at that load. In addition to this the Crown wheel was practically twice as strong as either of the others.

„In order to further test the strength of the Crown wheel, a new one was placed horizontally in the 200,000 pound testing machine. The rim was supported on two opposite sides of the hub for approximately a quarter of the circumference. It was then subjected to load by pulling downward on a bolt through the hub. No deflections were taken and no evidence of failure was noted until 24,500 pounds was registered, at which time a sharp cracking sound was heard. The cause of the cracking could not be found. After the load had been run up to 25,000 pounds, the pressure was taken off, the wheel removed and photographed.

„Since the Crown wheel, which was subjected to the load on the rim at the same time as the wood and wire wheels were, had been tested to destruction, it was thought worth while to subject one of these wheels to the same load that the wood and wire wheels failed under, to ascertain the condition of the wheel after the test. Accordingly a new wheel was mounted as shown in the illustrations and subjected to a rim load of 4,500 pounds. Upon removal from the machine the distortion was slight enough not to be noticeable.“

Photo captions.

Page 766.

Arrangement of testing wheels with the Riehle horizontal machine. Note special hub for each type of wheel. In the test the load was applied at the rim, the effect being the same as when the car skids and the wheel strikes a curb or some similar obstruction at the roadside. Two thousand pounds pressure was applied at first, and this was increased 500 pounds at a time during the tests

Page 767.

Left – Second test of Crown Prince wheel! with load applied at center and rim up to 25,000 pounds. Wheel badly bent but not fractured and could still be used. No sign of weld opening at any point, or any crack in the metal. The straight edge at the side gives a Left Center-Crown Prince wheel at 8,940 pounds when wheel had permanent deflection One spoke broke at Beam refused to balance at 4,000 pounds, and at this pressure two spokes gave way. Right-Appearance of wire wheel at failure. Most of spokes conception of the amount the wheel was bent. of 1 inch. One spoke pulled away at hub at 8,250 pounds. Right Center-Condition of wood wheel at failure. 1500 pounds, and complete failure at 4,500 pounds. Note substantial hub construction. Spokes broke at 4,000 pounds. broke 1½ inch from nipple in rim 2

After the publication of this test summary, a short discussion took place, of which the contents are shown here. GrocerJack.

The Automobile, Vol. XXVI (26), No. 18, April 30, 1914

Wheels Should Be Same Size and Weight in Tests

EDITOR THE AUTOMOBILE: – I noticed in an article published in THE AUTOMOBILE, April 9, describing a test of steel, wood and wire wheels, in which the steel wheel showed to advantage in that wheels of different sizes were used, and I consider the test highly unfair and practically meaningless because of this. The Crown Prince steel wheel was 35 by 4.5 inches, the wood wheel 34 by 4, and the wire wheel which I think was a McCue, 36 by 4.5.

As a champion of the wire wheel, the test to my mind is manifestly unfair, insomuch as they subjected a wire wheel of greater diameter to the strains of the testing machine than the steel wheel. Then, again, there is no comparison of weights between the different wheels and I understand that the wire wheel is materially lighter than the steel construction.

I think it is up to the Houk Mfg. Co. to show the relative merits of the different wheels and not permit a test of this nature to go unchallenged.

The public is hungering for data in regard to wire wheels and it seems to me that if the results of the Crown Prince test are not analyzed carefully the claim of superiority in the wire wheel will suffer unjustly. I would like to see a test made giving weights of the different wheels and using them all of the same diameter, preferably 34 by 4 inch sizes.

Chicago, Ill. THOMAS BOVEY.

The Automobile, Vol. XXVI (26), No. 20, May 14, 1914

Difference in Size of Wheels in Test Not Important

EDITOR THE AUTOMOBILE: – I would be very thankful if you would give Mr. Thomas Bovey of Chicago the following information. In reply to Thomas Bovey’s criticism of the test of the Crown Prince wheel appearing in THE AUTOMOBILE of April 30, I beg to say that on account of being unable to get wheels of exactly the same diameter and the test date drawing closer, I used the wheels in question. However, I consider that this is not very important, as the difference between the pressed steel and the wire wheel was only .5-inch. If anything the wire wheel had the advantage in this test as no doubt a 36 by 4.5 inch wheel is supposed to be stronger than a 35 by 4.5 inch, as it is designed for a larger car.

With reference to weight of the different wheels tested, I wish to say that the wire wheel tipped the scales at 46 pounds, the pressed steel at 39 pounds and the wood wheel at 33 pounds. This information was given in the original data on the test, compiled by the engineering staff of the University of Michigan, but was omitted in the article of April 9 on account of shortness of space.

For your further information I wish to point out that the pressed steel wheel is not heavier than the wire wheel, but weighs considerably less than a real wire wheel, I mean one that is made to suit American conditions and can be used without fear of continually breaking and bending spokes if this is possible at all.

There is no doubt whatever as to greater strength and general superiority of the pressed steel wheel over either the wood or wire wheel, otherwise it would not be conceivable that some of the foremost European automobile builders would be using the same in preference to both wood and wire wheels.

As to having the Houk Mfg. Co. take up this matter I wish to say that I have informed this company that I will be very pleased to have another test made and use a Houk wheel instead of the McCue type wheel, which was used. Detroit, Mich. MAX BACHEM.