Immediately after the first French Grand Prix in 1906, the technical oriented magazine OMNIA published this article on the winning Renault racecar. Next to the meany technical items of that car, the „jantes amovibles“ or removable rims were highlighted. Important is also the mentioning that Renault’s victory was not solely a consequence of these new and innovative wheel rims, as some other competitors also were equiped with similar rims and they were less or even not classified.

With authorisation of Conservatoire numérique des Arts et Métiers (Cnum) – https://cnum.cnam.fr

Text and photos compiled by motorracinghistory.com, translation by DeepL.com

OMNIA – Revue pratique de Locomotion Volume 1. — N° 27. – Saturday July 7, 1906.

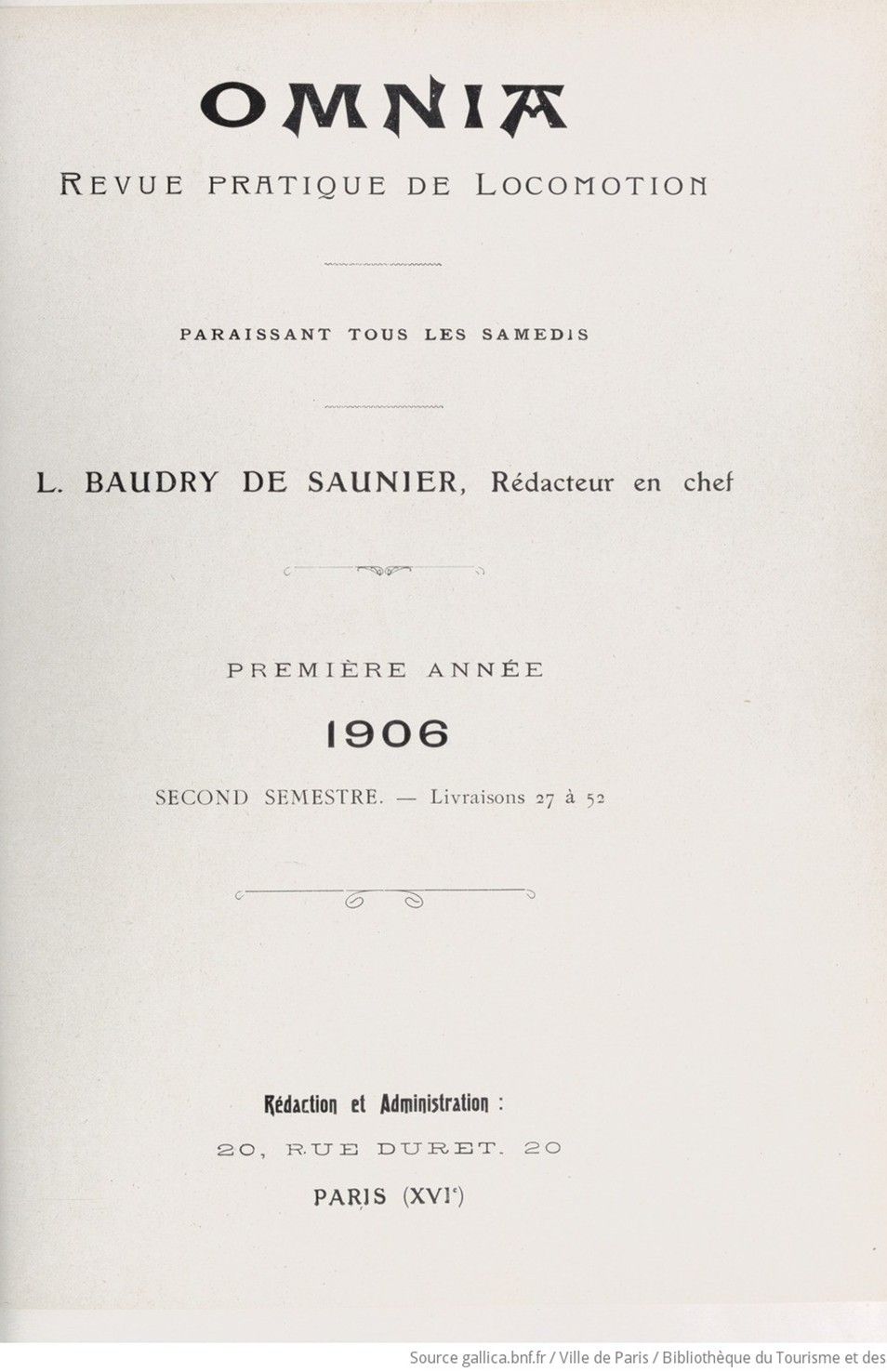

The Renault racing car that won the Grand Prix

The triumph of the Renault car at the Sarthe circuit was greeted with warm sympathy by the entire racing community. In more ways than one, the managers of the Billancourt factory have earned the esteem and admiration of all those who have followed the progress of our industry since its inception. We are particularly indebted to Louis Renault for significant improvements in cars, including the application of the cardan shaft system and the so-called direct drive system to gasoline-powered cars.

The car presented by Messrs. Renault brothers at the Sarthe circuit stood out from the other competitors at first glance thanks to its many original features; it distinguished itself in the race by its remarkable consistency.

In recent years, automobiles have reached such a degree of perfection that it has become very difficult to innovate. As a result, cars have come to resemble each other, not only in appearance, but also in the basic design of their mechanisms.

Our industry is experiencing what happened to the bicycle industry, which universally adopted the Humber frame, with the result that, apart from a few details, all bicycles look alike in every country.

In the A.C.F. race, two types of cars stood out clearly from the others thanks to several very distinctive features: the Darracq and the Renault. We will only discuss the latter, waiting to describe the former until they achieve resounding success, which should not be long in coming.

In the Renault, the distinctive features were mainly the multi-tube radiator, composed of very small-diameter tubes without fins, and the rear axle, whose narrow track width struck everyone. In addition, this car had a very low chassis: it was only 31 centimeters from the ground.

Features are only good if they are practical, which is the case with those of the Renault car.

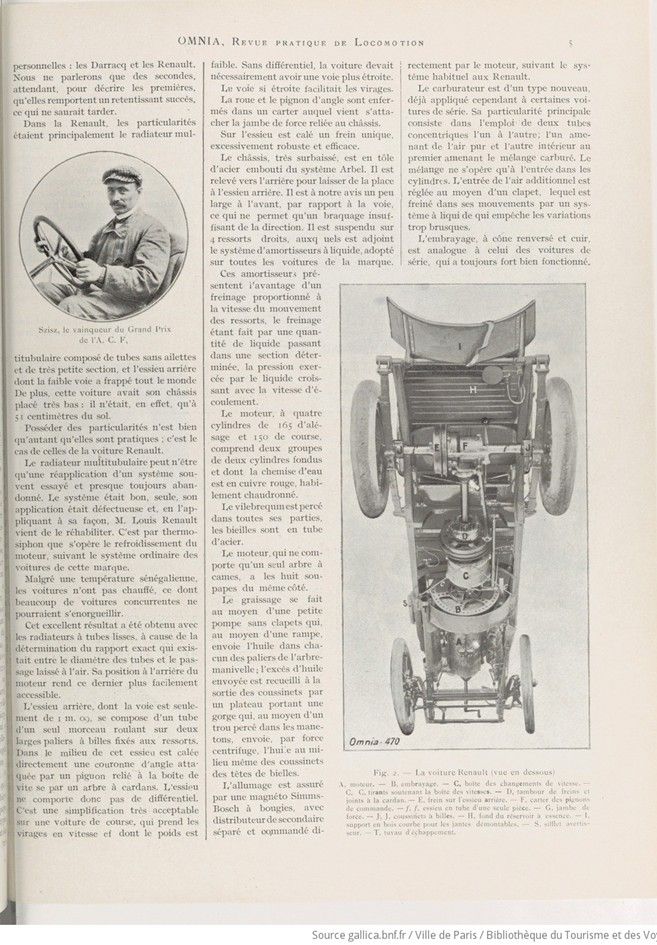

The multi-tube radiator may be nothing more than a reapplication of a system that has been tried many times and almost always abandoned. The system was good, but its application was flawed, and by applying it in his own way, Mr. Louis Renault has just rehabilitated it. The engine is cooled by thermosiphon, following the standard system used in cars of this brand.

Despite Senegalese temperatures, the cars did not overheat, something that many competing cars could not boast about.

This excellent result was achieved with smooth-tube radiators, thanks to the determination of the exact ratio between the diameter of the tubes and the passage left for the air. Its position at the rear of the engine makes the latter more easily accessible.

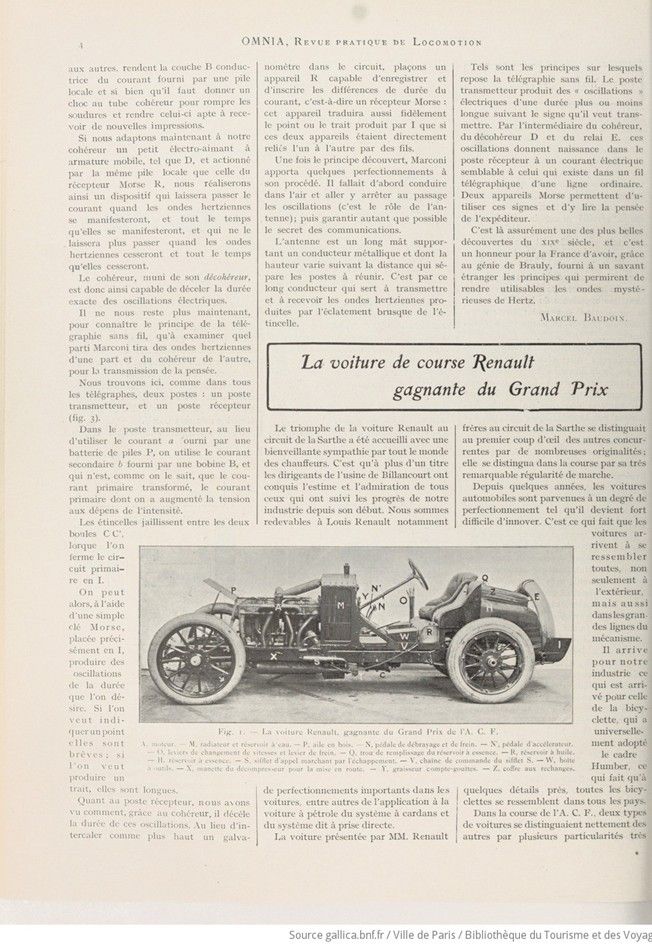

The rear axle, with a track width of only 1 m, consists of a single-piece tube rolling on two large ball bearings attached to the springs. In the middle of this axle is a bevel gear driven by a pinion connected to the gearbox by a cardan shaft. The axle therefore has no differential. This is a very acceptable simplification on a racing car, which takes corners at speed and is lightweight. Without a differential, the car necessarily had to have a narrower track.

The narrow track made cornering easier.

The wheel and angle pinion are enclosed in a casing to which the strut connected to the chassis is attached.

A single, extremely robust and effective brake is fitted to the axle.

The very low chassis is made of stamped steel sheet using the Arbel system. It is raised at the rear to make room for the rear axle. In our opinion, it is a little wide at the front in relation to the track, which means that the steering is insufficient. It is suspended on four straight springs, to which is added the liquid shock absorber system used on all the brand’s cars.

These shock absorbers have the advantage of braking proportional to the speed of movement of the springs, with braking being achieved by a quantity of liquid passing through a specific section, the pressure exerted by the liquid increasing with the speed of flow.

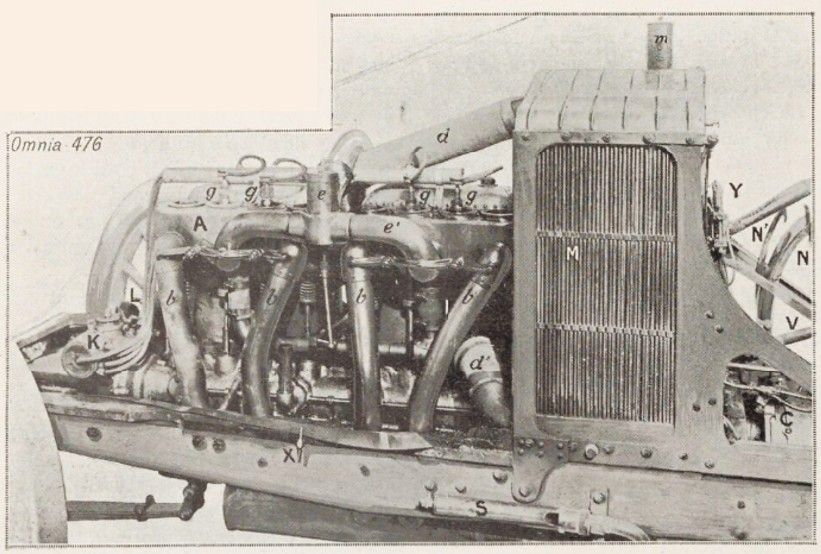

The engine, with four cylinders of 165 bore and 150 stroke, comprises two groups of two cast cylinders with red copper water jackets, skillfully crafted.

The crankshaft is drilled through in all its parts, and the connecting rods are made of steel tubing.

The engine, which has only one camshaft, has all eight valves on the same side.

Lubrication is provided by a small valve-less pump which, by means of a ramp, sends oil to each of the crankshaft bearings; any excess oil is collected at the outlet of the bearings by a plate with a groove which, by means of a hole drilled in the crankpins, sends the oil by centrifugal force to the center of the connecting rod bearings.

Ignition is provided by a Simms-Bosch magneto with spark plugs, with a separate secondary distributor controlled directly by the engine, following the system commonly used by Renault.

The carburetor is of a new type, already used in certain production cars. Its main feature is the use of two concentric tubes, one bringing in clean air and the other, inside the first, bringing in the fuel mixture. The mixture is only formed when it enters the cylinders. The intake of additional air is regulated by a valve, the movement of which is slowed by a liquid system that prevents sudden variations.

The clutch, with an inverted cone and leather, is similar to that of production cars, which has always worked very well.

The gearbox, which is very compact, has three speeds, the third of which is direct drive, and a reverse gear controlled by a special lever.

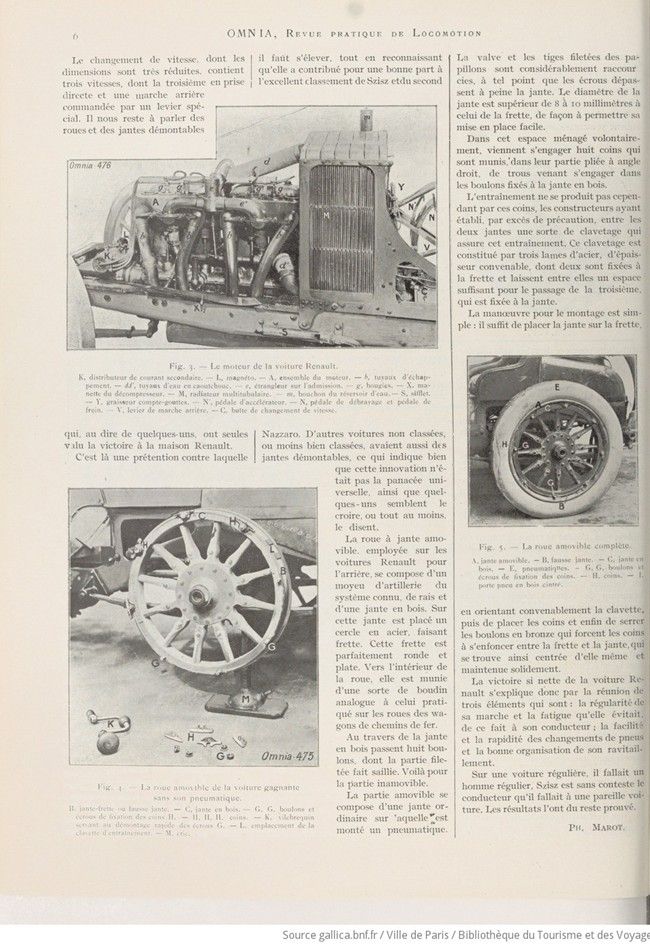

We still need to mention the wheels and removable rims, which, according to some, were the sole reason for Renault’s victory.

This is a claim that must be refuted, while acknowledging that it contributed significantly to the excellent ranking of Szisz and second-place finisher Nazzaro. Other cars that were not classified, or were less well classified, also had removable rims, which clearly indicates that this innovation was not a universal panacea, as some seem to believe, or at least say.

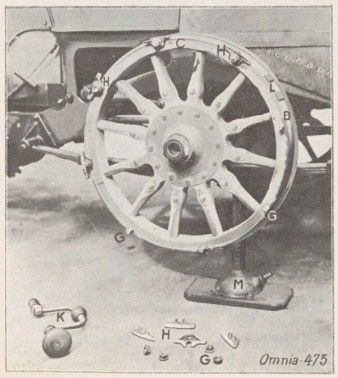

The wheel with a removable rim, used on Renault cars for the rear, consists of a hub of the known artillery system, spokes, and a wooden rim. A steel circle is placed on this rim, forming a band. This band is perfectly round and flat. Towards the inside of the wheel, it is equipped with a kind of bead similar to that used on railway carriage wheels.

Eight bolts pass through the wooden rim, with the threaded part protruding. That is the non-removable part.

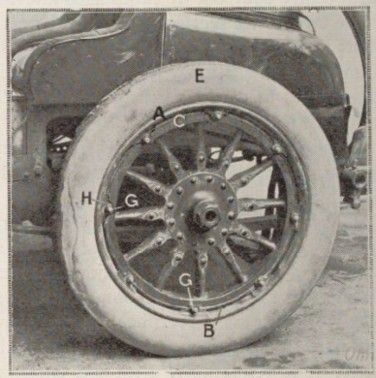

The removable part consists of an ordinary rim on which a pneumatic tire is mounted.

The valve and the threaded stems of the wing nuts are considerably shortened, to such an extent that the nuts barely protrude beyond the rim. The diameter of the rim is 8 to 10 millimeters greater than that of the tire, so that it can be easily fitted.

Eight wedges are inserted into this deliberately left space. These wedges have holes in their right-angled folded parts, which engage with bolts fixed to the wooden rim.

However, the drive is not provided by these wedges, as the manufacturers have, as an extra precaution, established a kind of keyway between the two rims to ensure the drive. This keyway consists of three steel blades of suitable thickness, two of which are fixed to the band, leaving enough space between them for the third, which is fixed to the rim.

The assembly procedure is simple: just place the rim on the band, orienting the key correctly, then place the wedges and finally tighten the bronze bolts, which force the wedges to sink between the band and the rim, which is thus centered by itself and held securely in place.

The clear victory of the Renault car can therefore be explained by the combination of three factors: the smoothness of its running, which prevented driver fatigue; the ease and speed of tire changes; and the good organization of its refueling.

A consistent car needed a consistent driver, and Szisz was undoubtedly the right driver for such a car. The results proved this.

Ph. MAROT.

Photos.

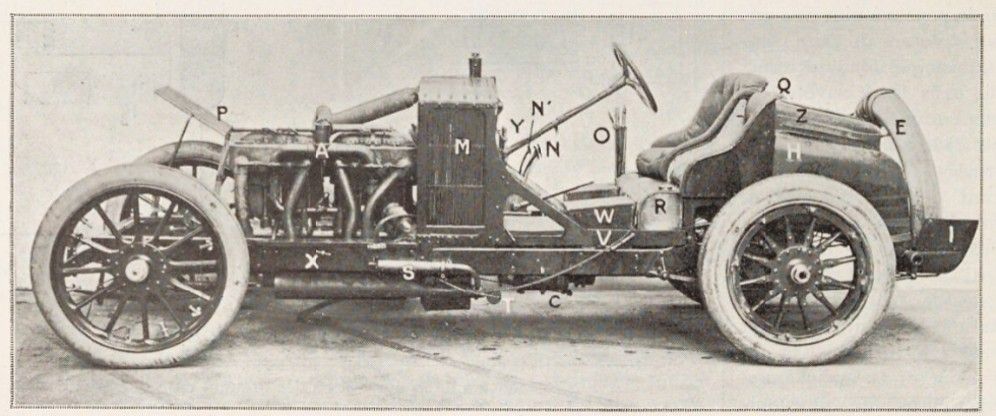

Fig. 1. — The Renault car, winner of the A.C.F. Grand Prix.

A. Engine. — M, radiator and water tank. – P, wooden fender. – N, clutch and brake pedal. — N‘, accelerator pedal. — 0, gear shift levers and brake lever. — Q, fuel tank filler hole. — R, oil tank. — H. fuel tank. — S, whistle operated by the exhaust. — Y, whistle control chain S. – W, toolbox. — X, decompressor lever for starting. — Y, drip oil can. —. Z, spare parts box.

Szisz. Winner of the A. C. F. Grand Prix.

Fig. 2. – The Renault car (view from below)

A. engine. — B. clutch. — C, gearbox. — C. C, tie rods supporting the gearbox. — 1), brake drum and cardan joints. – E, rear axle brake. — F, control gear housing. – f. f. single-piece tubular axle. – G. Strut. — J, J. Ball bearings. — Hl. Bottom of the fuel tank. – I. Curved boxwood support for removable rims. — S. Warning whistle. — T. Exhaust pipe.

Fig. 3. — The Renault car engine.

K, Secondary current distributor. — L, magneto. — A. engine assembly. — b, exhaust pipes. — dd‘, rubber water pipes. — e, choke on the intake, — g, spark plugs. — X. decompressor lever. — M, multi-tube radiator. — m, water tank cap. – S, whistle. — Y. Drip oiler. — X‘, accelerator pedal. — 1’\, clutch pedal and brake pedal. — N‘, reverse gear lever. — C. Gearbox.

Fig.4. — The removable wheel of the winning car without its tire.

B. Rim or false rim. — C, wooden rim. — G. G. Bolts and nuts for securing the corners Il. — H. H. H. Corners. — K. Crankshaft used for quick removal of nuts G. — L. Location of the drive key. — M. Jack.

Fig. 5. — The complete removable wheel.

A, removable rim. – B, false rim. — C, wooden rim. — K, tires. – G. G, bolts and nuts for fixing the corners. — II. corners. — curved wooden tire holder