Mid December 1909, the Indianapolis Speedway had completely been bricked. In this The Automobile issue, the entire process of brick manufacturing is explained. From the beginnings of the clay, through pressing it into the brick-form, via the drying and the burning and annealing. Then how they „Bricked the Yard“ and facilities that additionally were built on the Speedway premisses.

Text and jpegs by courtesy of hathitrust.org www.hathitrust.org, compiled by motorracinghistory.com

THE AUTOMOBILE, Vol. XXI, No. 25, December 16, 1909

INDIANAPOLIS SPEEDWAY IS READY

BY THOS, J, FAY

INDIANAPOLIS, IND., Dec. 14 – With every brick laid except one, the Indianapolis Motor Speedway awaits its official reopening on Friday and Saturday of this week. This missing brick is a gold-plated one weighing 52 pounds and valued at $500. Of course it will be watched until the conclusion of the meet, after which its future resting place will be decided upon. Drivers of international repute will participate in the competition and time trials, and it is anticipated that many new records will be established during the two-day meet, provided the winter weather conditions are not unnecessarily severe. All who are connected with the enterprise are most enthusiastic and good records are promised.

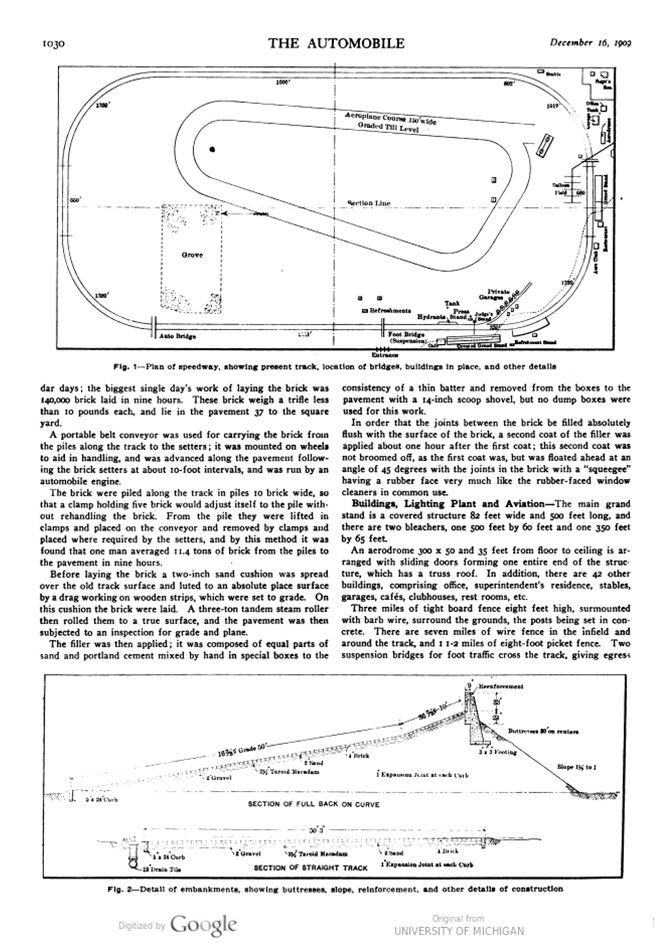

The earlier speeding attempts on the Indianapolis track proved that after a certain velocity is attained, cars, unless they are almost unbreakable, will give way under work they are required to do, even when the road is better than the standard set for ordinary road building. On account of the unfortunate accidents that befell some of the racing automobiles during the opening meeting held at the speed- way, which opened August 19 last, it was decided that nothing but the best possible pavement could be accepted, and the work of brick-paving has been under way ever since, culminating in the most perfect track possible to design and build, the dimensions being as in Fig. 1.

Brick Pavement Finally Decided Upon – That the original track, so well constructed as it proved to be, will serve as a most capable „base fill” is conceded by all the road engineers who were consulted before the work of brick-paving was undertaken. The resurfacing, which was necessary, was well executed, as indicated in the statement here afforded as prepared by Park Taliaferro Andrews, holding the official position of chief engineer of the speedway. The engineer’s resumé was gotten out by Mr. Andrews especially for THE AUTOMOBILE, and the author, having gone carefully over the whole work, is able to accept the engineer’s resumé in the light of a most guarded statement of actual fact, to which nothing of value can be added.

The life of this brick-paved track, however, is as yet to be determined, and this phase of the problem, while it may be regarded as well looked into, must be to some extent considered within speculative confines and entitled to a little discussion at this time. That there is nothing new about brick may be readily shown; they were used in the Tower of Babel; about this time, so it is recorded, they were also made by the children of Israel, in Egypt, under the Pharaoh. To indicate, however, the uncertain history of this industry, it is only necessary to point out that pottery, which is akin to brick, was a product of cave-dwellers of the drift period from the Neolithic.

Modern brick were first used, according to the most authentic sources of information, at Suffolk, in England, in the year 1260. In a hundred years from this time they were of fairly good manufacture, and in 1660 were in quite common use in London.

First Brick Kiln in America – At Salem, Mass., in 1629, the first brick kiln was probably established, although for many years nearly all brick used in this country came from Holland or England. Paving brick, which are of recent origin, were first used in this country in 1870, as nearly as present sources of information can be relied upon.

Process of Manufacture Defined – In the manufacture of paving brick there are many points to consider that do not have to be taken into account in connection with the manufacture of brick for building. From a suitable deposit of clay or shale the material is selected with the greatest care, crushed in dry pans or milled in solid rolls, they being about 48 inches in diameter and one foot wide. The rolls revolve within a revolving pan as much as 108 inches in diameter, the same being provided with a grated bottom. For a large-sized brick machine, two such pans are required, and the amount of shale crushed per hour lies between five and ten cubic yards; about two cubic yards of material is required per thousand of brick.

The crushed material is screened in a process involving fixed and shaking riddles, and knockers are employed to prevent the wet clay from sticking. From the screening process with its attending difficulties, which will not be discussed here, the clay goes to the “pugging” process, where the screened material is rendered plastic in form by suitable additions of water during the process of working in a properly contrived pug-mill. Pugging must be thoroughly done to remove air-enclosures, secure homogeneosity and reduce laminations to a minimum.

When the clay is well crushed, tempered and worked, which for the best results is frequently done by the wet-pan process, moulding follows. In moulding there is the “stiff-mould” process, which seems to be the more promising, despite frequent attempts to apply the dry-press system. A continuous working auger in the stiff-mud process forces the mud through forming dies, when the bar is sanded to prevent the brick from sticking together in the kilne. The bars, as they emerge from the forming dies, are cut to the required length, and a machine, under well-working conditions, is good for 100,000 bricks per day.

The repressing process, when it is applied, consists in putting freshly made stiff-mud brick into a die-box and subjecting it to a heavy vertical pressure, applied, as a rule, to the flat side. This process has the virtue of filling out the angles and edges, making the brick much more dense and uniform.

Drying is done by placing the brick on cars in a checkerwork fashion as high as possible within the sustaining ability of the stiff-mud condition of the brick to be dried, and the cars, so loaded, are run into drying chambers.

Burning, disregarding for the time the quality of material, is the most important process, for no matter how good the work may be done up to this process, No. I paving brick can only be the result of proper burning, and it is just here that the skill of the expert counts for everything. Burning usually takes place in from seven to ten days, and as to temperature, a shale brick requires from 1,500 to 2,000 degrees Fahrenheit, while brick made of fire clay demands from 1,800 to 2,300 degrees Fahrenheit.

Annealing follows, after the vitrifying temperature has been maintained for a sufficiently long time to heat the brick through to the center, which annealing is done by closing the kilns and allowing the brick to cool very slowly. For No. I brick, annealing should take from seven to ten days. Sorting follows after annealing, and in a properly processed batch of brick it is possible to realize fully 90 per cent. of No. I pavers. In this sorting, owing to many difficulties, mistakes are likely, and in the selection of paving brick for a job such as this, it is necessary to exercise the greatest care.

Engineers Had Many Difficulties to Guard Against – While the history of brick making is that of the human race, almost, even so, in view of the uncertainties involved, the selection and use of over 500 carloads of paving brick for this job represented a deal of painstaking labor, which involved divers precise detailed operations, some of which, however, was avoided, on this occasion, due to the care exercised in the earlier effort dating before it was decided to pave the course.

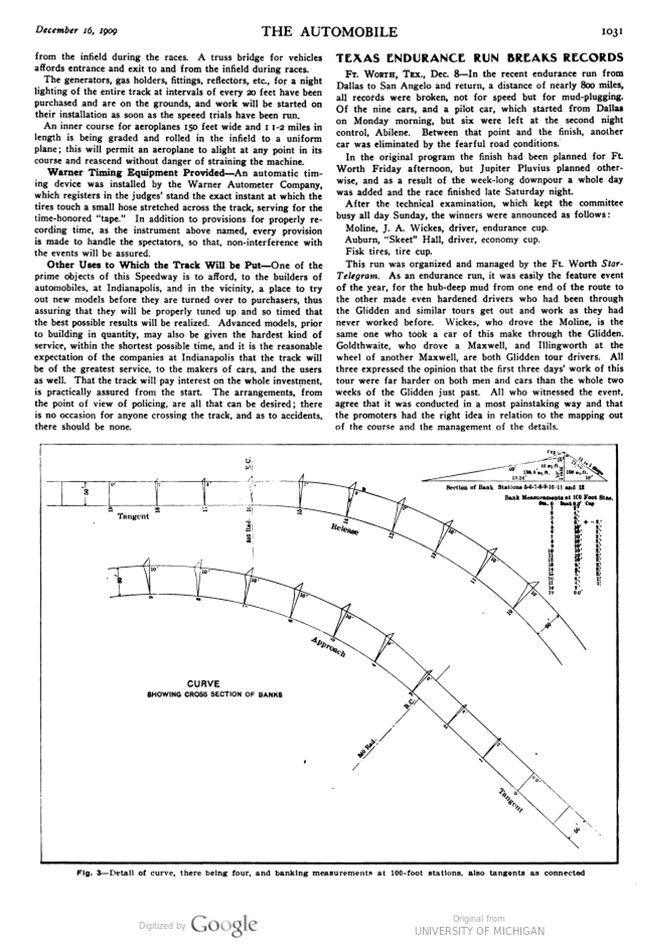

Methods Employed During the Whole Process — The course is two and one-half miles, being 50 feet wide on the straight stretches and 60 feet wide on the curves. The home-stretch and back-stretch 3,301 feet long, the end straights being 660 feet long, and each of the banked turns being 1,320 feet long on the course line. The curves are each 1-4 of a circle of 840 feet radius on the course line, or 90° of a 6° 49′ 30″ curve. No easement curves or spirals were used.

The curves are banked to an angle of 16° 40″ in cross-section for 50 feet of their width, the remaining 10 feet of width being banked to an angle of 36° 40″, all, as shown in Figs. 2 and 3. The approaches and releases to and from the banked curves are limited to a 2 per cent. grade in sections parallel with the measured course line, and the maximum variation from a level plane at the course line is a 2-10 per cent. grade. The straight stretches are given a pitch of 8-10 feet in 50 feet toward the infield for drainage, thus presenting a fine flat track for the cars.

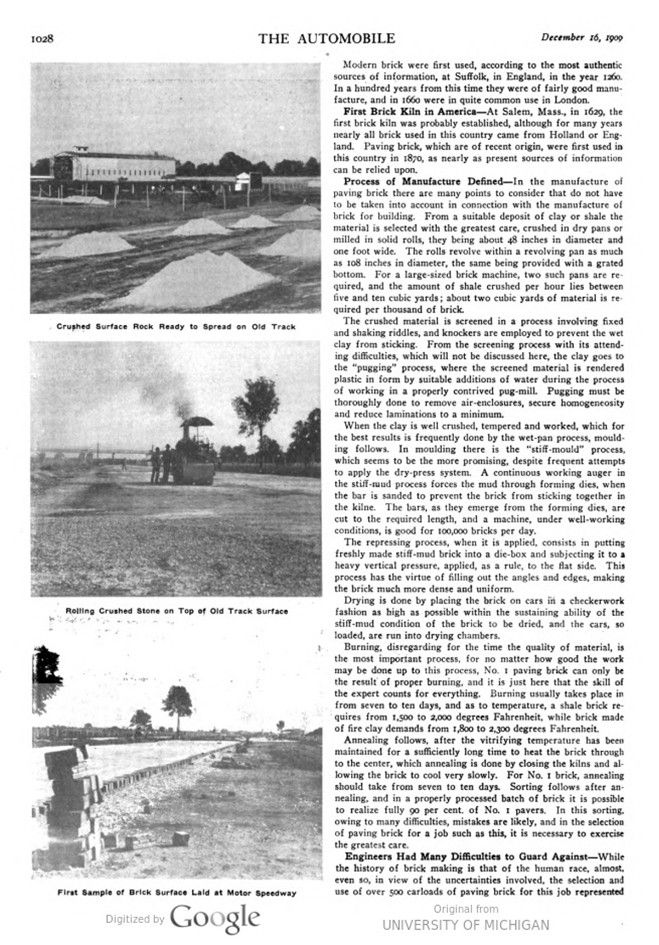

Base Fill Was Thoroughly Rolled — With a 15-ton three-wheel steam roller the whole course was resurfaced and rerolled until the surface presented a smooth, firm and uniform plane. Two inches of creek gravel was then spread uniformly over the entire surface and rolled with the 15-ton roller. This was followed by a 2-inch layer of crushed limestone (rolled with 8-ton tandem roller), over which was poured two gallons of taroid tu the square yard; this surface was then overcast with 1-2-inch crushed stone chips, filling the voids between the larger-size stoi!e, and given another coat of taroid (of a lower melting point than the first coat), 8-10 gallon to the square yard being used in the second coat. Over this was spread a thin layer of crushed stone from 1-2-inch to dust in size, and given a final rolling with a 3-ton tandem steam roller.

This surface, which represented the original idea, did not prove to be satisfactory, and the idea of paving over this surface with brick is the matter with which we are now concerned. In proceeding with the brick paving it was decided to accept the No. 1 specifications of the National Paving Brick Manufacturers‘ Association, and 3,200,000 pressed paving brick were ordered from the Wabash Clay Company for the purpose.

The association, realizing the opportunity for a practical demonstration of brick as a paving material, has collaborated with the engineers of the speedway company, and has furnished two of its ablest men, viz. : W. T. Blackburn, of Paris, Ill., and C. G. Moore, of Cleveland, O. These men have acted as inspectors and advisory engineers.

The pavement has been carefully inspected as it progressed, every square yard of its surface being covered with a 12-foot straight edge, and any variation exceeding 3-8 inch in the 12-foot length removed before the grout was applied to the brick. Along each side of the straight stretches and around the inside of each curve a 5″ x 24″ concrete curb was placed, the top being flush with the surface of the pavement, and a 1″ expansion joint being provided between the pavement and the curb. No transverse expansion joints were used. At the outside of the pavement on each of the banked curves, and in front of the main grand stand, a 9-inch reinforced concrete wall 33 inches above the track surface has been built.

Two reinforced concrete bridges were built to support the track over a stream running diagonally across the southwest corner of the grounds. These bridges are 30 feet wide and 90 feet long, of a permanent character located as shown in Fig. I.

Drainage Regarded as Extremely Important – 14.3 miles of tile have been laid to drain the grounds, the water which falls on the track being taken care of by a surface drainage system with flush gratings placed equidistant and three feet from the inside of the track. Agriculture drains have been used to care for the ground water.

Methods Employed in the Big Undertaking – The owners have conducted nearly all of the work themselves, only two contracts being entered into, one of which was rescinded owing to the contractor’s failure to prosecute the work. The earth work, grading and forming the base fills, etc., was contracted by the C. C. King Bros. & Son Company, who used two outfits of the Western Elevating Grader drawn by traction engines, loading bottom-dump wagons.

As an auxiliary to these outfits, two gangs of wheeled scrapers were used, and between 2,000 and 3,000 yards of average cut and fill was moved daily by this means, the contractors completing their work within the time limit of 60 days in a satisfactory manner. A contract was also entered into for a portion of the brick paving, but the owners were forced to rescind and prosecute the work themselves.

Over 500 carloads of brick were required for paving and in the cement filler between the brick, and the concrete work incident to the track over 80 carloads of cement were used, 53 being used for the grout filler in the brick pavement alone. The entire brick paving of the track was completed in 63 consecutive calendar days; the biggest single day’s work of laying the brick was 140,000 brick laid in nine hours. These bricks weigh a trifle less than 10 pounds each, and lie in the pavement 37 to the square yard.

A portable belt conveyor was used for carrying the brick from the piles along the track to the setters; it was mounted on wheels to aid in handling, and was advanced along the pavement following the brick setters at about 10-foot intervals, and was run by an automobile engine.

The brick were piled along the track in piles 10 brick wide, so that a clamp holding five brick would adjust itself to the pile without rehandling the brick. From the pile they were lifted in clamps and placed on the conveyor and removed by clamps and placed where required by the setters, and by this method it was found that one man averaged 11.4 tons of brick from the piles to the pavement in nine hours.

Before laying the brick a two-inch sand cushion was spread over the old track surface and luted to an absolute place surface by a drag working on wooden strips, which were set to grade. On this cushion the brick were laid. A three-ton tandem steam roller then rolled them to a true surface, and the pavement was then subjected to an inspection for grade and plane.

The filler was then applied; it was composed of equal parts of sand and portland cement mixed by hand in special boxes to the consistency of a thin batter and removed from the boxes to the pavement with a 14-inch scoop shovel, but no dump boxes were used for this work.

In order that the joints between the brick be filled absolutely flush with the surface of the brick, a second coat of the filler was applied about one hour after the first coat; this second coat was not broomed off, as the first coat was, but was floated ahead at an angle of 45 degrees with the joints in the brick with a „squeegee“ having a rubber face very much like the rubber-faced window cleaners in common use.

Buildings, Lighting Plant and Aviation – The main grand stand is a covered structure 82 feet wide and 500 feet long, and there are two bleachers, one 500 feet by 60 feet and one 350 feet by 65 feet.

An aerodrome 300 x 50 and 35 feet from floor to ceiling is arranged with sliding doors forming one entire end of the structure, which has a truss roof. In addition, there are 42 other buildings, comprising office, superintendent’s residence, stables, garages, cafés, clubhouses, rest rooms, etc.

Three miles of tight board fence eight feet high, surmounted with barb wire, surround the grounds, the posts being set in concrete. There are seven miles of wire fence in the infield and around the track, and 1 1-2 miles of eight-foot picket fence. Two suspension bridges for foot traffic cross the track, giving egress from the infield during the races. A truss bridge for vehicles affords entrance and exit to and from the infield during races.

The generators, gas holders, fittings, reflectors, etc., for a night lighting of the entire track at intervals of every 20 feet have been purchased and are on the grounds, and work will be started on their installation as soon as the speeed trials have been run.

An inner course for aeroplanes 150 feet wide and 1 1-2 miles in length is being graded and rolled in the infield to a uniform plane; this will permit an aeroplane to alight at any point in its course and reascend without danger of straining the machine.

Warner Timing Equipment Provided – An automatic timing device was installed by the Warner Autometer Company, which registers in the judges‘ stand the exact instant at which the tires touch a small hose stretched across the track, serving for the time-honored “tape.” In addition to provisions for properly recording time, as the instrument above named, every provision is made to handle the spectators, so that, non-interference with the events will be assured.

Other Uses to Which the Track Will be Put – One of the prime objects of this Speedway is to afford, to the builders of automobiles, at Indianapolis, and in the vicinity, a place to try out new models before they are turned over to purchasers, thus assuring that they will be properly tuned up and so timed that the best possible results will be realized. Advanced models, prior to building in quantity, may also be given the hardest kind of service, within the shortest possible time, and it is the reasonable expectation of the companies at Indianapolis that the track will be of the greatest service, to the makers of cars, and the users as well. That the track will pay interest on the whole investment, is practically assured from the start. The arrangements, from the point of view of policing, are all that can be desired; there is no occasion for anyone crossing the track, and as to accidents, there should be none.

Photo captions.

Top Roller at 36 Degree Embankment – Belt Conveyor in Process of Laying Pavers

Crushed Surface Rock Ready to spread on Old Track – Rolling Crushed Stone on Top of Old Track Surface – First Sample of Brick Surface Laid at Motor Speedway

Cleaning up the Completed Surface

Fig. 1-Plan of speedway, showing present track, location of bridges, buildings in place, and other details

Fig. 2 Detail of embankments, showing buttresses, slope, reinforcement, and other details of construction

Fig. 3 Detail of curve, there being four, and banking measurements at 100-foot stations, also tangents as connected